Dosing is one of the most important manufacturing process steps for dehydrated products for any dry food packaging facility. It has a major influence on consumer quality and perception and an important influence on cost. When dosing isn’t done properly, i.e. with the wrong equipment or parameter settings, it will lead to undesired organoleptic changes in relation to particle size, viscosity and mouth feel. Inappropriate dosing will also lead to greater dosing deviations resulting in higher raw material cost through overdosing and also waste caused by rejected underweight pouches.

This best practice document provides a guideline to the selection of appropriate dosing equipment for dehydrated products. Appropriate dosing systems must meet quality levels as agreed between Marketing and R&D, meet legal requirements and operate according to agreed good manufacturing practice.

The document contains general information on dosing techniques, describes relevant technical parameters and also gives the specific advantages and disadvantages of the various dosing systems. Also relevant product parameters, such as flowabilty and particle size, are described.

Weight control statistics are explained and guidelines are given as to how product and process specifications should be set up to guarantee quality levels.

A main selection matrix will lead through dosing possibilities on the basis of ingredient properties. This approach will indicate the most suitable dosing unit for the specific situation. The selection process also indicates which dosing methods are less suitable or not suitable for the given application.

The outcome of the evaluation will also indicate whether a product can be dosed on existing dosing equipment in accordance with GMP, at the desired quality level and legal requirements.

These guidelines are to guarantee optimal quality and manufacturing cost. Other proposed solutions can only be used after consultation with the responsible global supply chain group. The supply chain group will decide on deviation from current best practice in close co-operation with the respective community of practice.

This approach will contribute to the global standardisation of dosing techniques and thus to the quality of dosing applications. The document shall be updated continuously so that that the latest information can be made available.

A knowledge structure for keeping the technical know how up to date is embedded within the organisation. This structure operates with local and global focal points. Local focal points are the responsibility of engineering. The global focal points, i.e. the global supply chain group, have the responsibility to update best practice documents.

1. Introduction

This best practice document covers dosing methods for dehydrated savoury products. The objective of the document is to facilitate the selection of optimum dosing equipment. A good match between dosing equipment and raw materials will lead to consistent product quality and cost reduction through improved dosing results.

This document is applicable for all PTG´s (product technology groups). Key subjects which are covered in the document are ingredient behaviour (flowability), different types of dosing methods, dosing accuracy and selection of dosing equipment. A short overview of the relevant document sections is given below.

Ingredient behaviour

Predicting the flowability of dehydrated products is difficult as real products typically contain ten to twenty different ingredients. Fat content and particle size are main determining factors for flowability.

Accuracy

The accuracy of dosing can be described by its standard deviation. In daily practice dosing standard deviations are frequently near, or above the quality limits or the local legislation. As a consequence, over- and under- dosing might result in rejects. Examples will indicate how dosing accuracy impact the weight control set point and/or product rejects.

Dosing techniques

Sketches, photos and a brief description explain the different dosing techniques. A description of advantages and disadvantages of these techniques is provided.

Selection of dosing equipment

A matrix is provided to enable selection of the most suitable dosing equipment for a particular application. The following dosing types are covered:

- Auger

- Piston

- Cup

- Sliding gate flat

- Sliding gate tube

- Linear scale

- Multi-head scale 8, 9, 10, 14, 16, 24, 32, 48 heads

- Loss in weight feeder

- Belt scale

- Belt feeder

- Vibrating funnel

- Volumetric dosing

2. Product Know-how

In order to understand the flowability of powders and particles, it is necessary to understand the interaction between the particles and the interaction between the particles and equipment. The nature of these interactions determines the behaviour of powders in specific dosing equipment.

Powder properties can be assessed through various types of test equipment. Many of these tests provide qualitative results and enable a comparative analysis only. The tests do give an indication of flowability and can be used as a basis for dosing equipment selection. To ensure that a dosing system will meet the required capability and accuracy requirements in practice, test runs with the dosing system and actual product are always necessary.

3. Dosing Technology in Food Manufacturing

3.1. Dosing technology – Introduction

The two key criteria in selecting a dosing method are product behaviour and the required accuracy of the dosing system.

Product flowability is an important factor in equipment selection. Some products will flow under gravity whilst others have to be transported by mechanical means. Moisture, fat and oil content generally have a significant impact on the flowability of the product and may lead to specific dosing equipment requirements.

The ingredients have to be transported from a hopper to the dosing system. In general the hopper has a large diameter outlet in order to minimise bridge formation and breakage of particulates in order to guarantee an uninterrupted flow. Typically transport screws or belt conveyors are used to discharge hoppers. These transport systems have to ensure a gradual feeding of the dosing system. The product quality has to be consistent; caking, agglomeration and separation of particles have to be avoided during transport and dosing. The focus of this section of the document will be on the different types of dosing methods/equipment.

A volumetric dosing system which operates under the assumption that product density is constant. For solids this is rarely true. As a result, proportioning devices rely heavily on either having constant density or relatively uniform density which varies only slightly over time. In order to guarantee the net weight in the pouch a check weigher needs to be installed downstream of the filler. Using software to calculate trends, the check weigher sends a signal to the proportioning device to increase or decrease the dosing time or volume as required.

The following dosing methods are described:

- Auger (volumetric method);

- Piston (volumetric method);

- Cup (volumetric method);

- Sliding gate flat (volumetric method);

- Sliding gate tube (volumetric method);

- Linear scale (gravimetric method);

- Multi-head scale 8, 9, 10, 14, 16, 24, 32 heads (gravimetric method);

- Loss in weight feeder (gravimetric method);

- Belt scale (gravimetric method);

- Belt feeder ( volumetric method);

- Vibrating funnel (volumetric method);

- Volumetric dosing.

The majority of the dehydrated dosing equipment should be an intermittent type. Some continuous dosing equipment is used. This type of equipment can reach a dosing velocity of above 1000 packages per minute, depending on the type of product and the type of package and its desired weight.

3.2. Overview of dosing technologies

3.2.1. Auger dosing unit

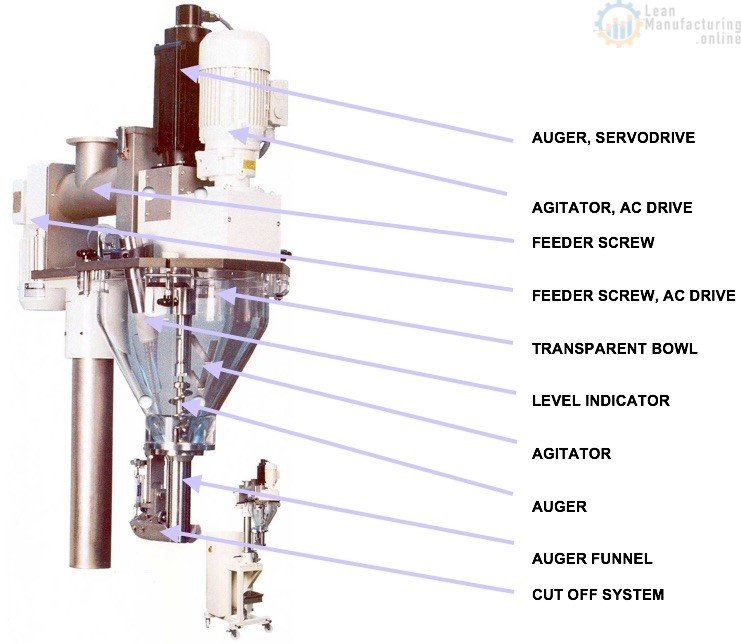

The auger dosing unit, is a screw type unit. Powder is usually fed into a bowl by a horizontal conveyor screw. The product is dosed from the bowl by a vertical auger.

Auger dosing unit

This intermittent proportional system doses a given volume of material in a given period of time, based on variable auger speed, in a primary packaging system (e.g. pouch). To keep the density of the product stable the level in the bowl has to be constant. This is achieved through a level sensor, which controls the speed of the feeder screw. An agitator has been fitted in the bowl to prevent the powder from compacting and to ensure a uniform powder distribution in the bowl.

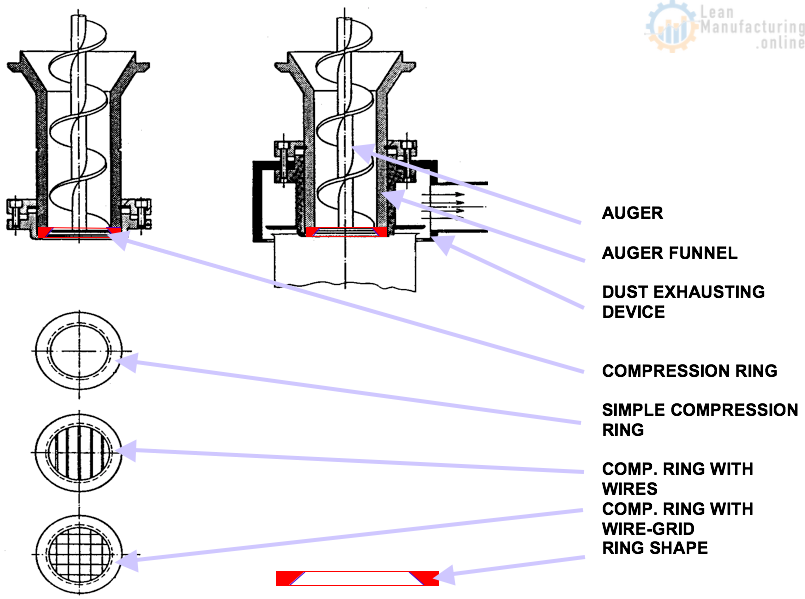

Sketch of auger and compression rings

When the auger is running, the compression ring will give a certain resistance to the powder just to ensure that the right volume with the right density is dosed.

If the auger has dosed the right amount and is stopped, the wire or grid in the compression ring will create enough resistance to avoid unwanted flowing of powder. The type of grid or wire that will be used depends on the type of material to be dosed. Different configurations are used for powders with a particulate mixture.

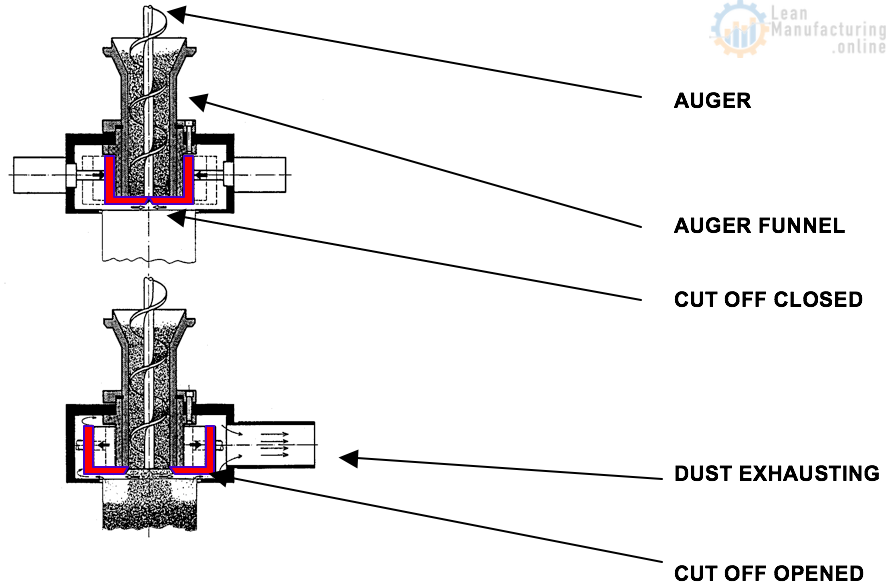

Sketch of operation of the cut off ring

A cut off device will be used when a compression ring, wire or grid is not sufficient, e.g. when dosing free flowing powders.

Sketch of auger with spinner plate and collector funnel

For free-flowing powders and powders with particulates this spinner assembly with collector funnel gives an improved controllability of dosing.

Sketch of three different type of augers

A: Auger with spinner plate;

B: Normal auger (diameter = pitch);

C: Compression auger.

Specific types of augers are used depending on product behaviour. Spinner plate augers are used for free-flowing products, as these reduce powder flowability and improve dosing control. A normal auger will dose product with an average flowability and the compression auger is used for non-free flowing product in order to avoid bridging.

3.2.1.1. Application of the auger dosing unit

The auger dosing unit is a universal dosing system for powders and powder mixes. These units are not ideally suited for dosing high fat content powders and dosing of particulates. Powders with a high liquid fat content will cause smearing of the auger and the funnel which will influence the dosing accuracy and product quality. Particulates or other sensitive ingredients (e.g. herbs) can get damaged in the auger which negatively affects the quality of the packed product. For these products, also segregation may occur which will affect the uniformity of the finished product.

3.2.1.2. Advantages

– Universal volumetric dosing system for powders and powder mixes;

– High accuracy for free-flowing products;

– Easy to operate

– Easy to clean (normally dry);

– Easy change over, normally only change of auger and funnel for different dosing volumes and a change of parameters in memory of PLC;

– Easily adjustable;

– Limited maintenance requirements;

– Closed dust reduction system.

3.2.1.3. Disadvantages

– Limited use for high fat products;

– Limited use for products with poor flowability;

– Limited use for particulates or mixes with particulates.

3.2.1.4. Equipment

– Independent drives;

– AC drive for horizontal feeding screw with frequency control;

– Servo drive for auger;

– AC drive for agitator with frequency control;

– Transparent hopper/bowl, two separate halves; one fixed, the other removable.

– Level sensor/indicator for hopper/bowl, adjustable in height;

– Different compression rings for funnels;

– Some flyers (ref. figure 16) for product flow support on top of the augers;

– Cut off device below the auger (if needed);

– Dust exhausting funnel/ring on the product exit of the auger (if needed);

– Nitrogen injection device (if needed);

– Independent PLC control system with interface to dosing machine and check weigher;

– Remote control (tendency control) system in connection with the check weigher for automatic weight adjustment;

– Interface signal exchange for no box/pouch no fill;

– Interface signal exchange for sequential start and stop of the dosing unit.

3.2.2. Piston dosing unit

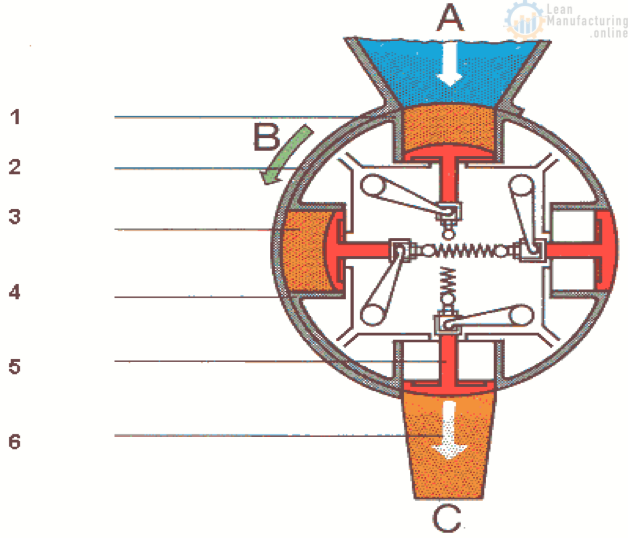

The piston dosing unit consists of a vertical rotating disc which contains two or more cylinders. Each cylinder contains a piston and will receive product from a feeding hopper or through a pipe connection. After the disc rotates through 180 degrees, the piston will dose the ingredient into the primary packaging (ref. figure 9). This is a volumetric dosing method and a checkweigher will be needed to ensure adequate weight control.

Scheme of piston dosing unit

A charging

B movement of the rotor

C Discharge

- Cylinder;

- Cover of rotor;

- Dosing chamber;

- Rotor;

- Piston;

- Filling chute.

3.2.2.1. Application of piston dosing unit

The piston dosing unit may be used for dosing of powder mixes, particulates, vegetables, noodles and rice. The unit is, however, not recommended for low to medium speed packing lines because of its cost and mechanical complexity.

3.2.2.2. Advantages

– Suitable for dosing of free flowing components such as particulates (dried vegetables, noodles, rice and others) but also for powder mixes with particulates;

– Good accuracy because of positive filling and emptying of the dosing chambers;

– Easy to operate

– Easy to clean (normally dry);

– Easily adjustable;

– Closed dust reduced system;

3.2.2.3. Disadvantages

– Limited use for powders and powder mixes, especially on high liquid fat content or poor flowability powders;

– Some particulate damage due to piston action;

– Time consuming change over as this requires a change of complete sets of feeding pipes, pistons and cylinders (2, 4, 8 or more);

– Moderate maintenance frequency required;

3.2.2.4. Equipment

– Independent drives;

– AC or servo drive for rotating turret (moving inner frame);

– AC or servo drive for piston movement;

– Transparent feeding pipe (light conical if possible) or transparent hopper with agitator;

– Level sensor/indicator for feeding pipe, adjustable in height;

– Filling funnel equipped with vibrating unit;

– Dust exhausting funnel/ring on the product exit (if needed);

– Independent PLC control system with interface to dosing machine and check weigher;

– Remote control (tendency control) system in connection with the check weigher for automatic weight adjustment;

– Interface signal exchange for no box/pouch no fill;

– Interface signal exchange for sequential start and stop of the dosing unit.

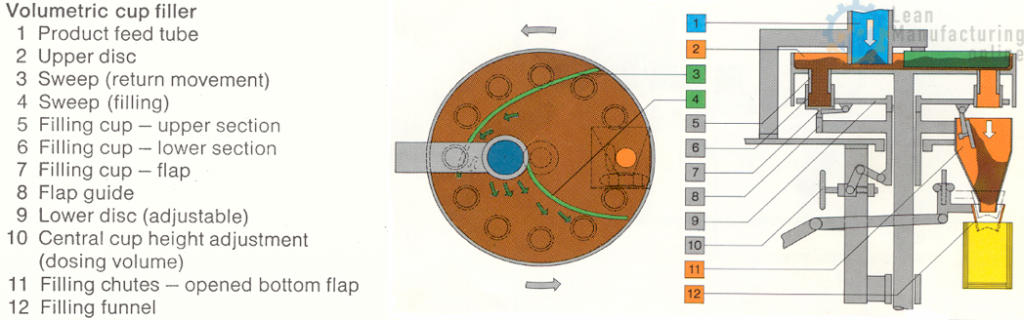

3.2.3. Cup dosing unit

A rotary cut off volumetric cup dosing unit can be equipped with cups for various volumes. This type of dosing unit can be applied in multi-product lines and can handle fragile products with minimal damage.

Volumetric 6 Cup dosing unit

Scheme of cup dosing unit

3.2.3.1. Application of a cup dosing unit

A cup dosing unit is a universal dosing system for particulates e.g. vegetables, pasta and rice, but has a limited accuracy.

3.2.3.2. Advantages

- Special volumetric dosing system for free-flowing components, mainly for particulates (dried vegetables, noodles, rice and others);

- Acceptable accuracy because of scraping the mass into the dosing chambers;

- Easy to operate;

- Easy to clean (normally dry);

- Easily adjustable;

- Limited maintenance.

3.2.3.3. Disadvantages

– Very limited use for powders and powder mixes, especially on high fat content or poor flowability powders;

– Time consuming change over because a complete set of pistons and cylinders (2, 4, 8 or more) has to be replaced if another dosing volume is required.

3.2.3.4. Equipment

– Independent drives;

– AC or servo drive for rotating turret (moving inner frame);

– AC or servo drive for piston move;

– Transparent feeding pipe (light conical if possible);

– Level sensor/indicator for feeding pipe, adjustable in height;

– Dosing funnel equipped with vibrating unit;

– Dust exhausting funnel/ring on the product exit (if needed);

– Independent PLC control system with interface to dosing machine and check weigher;

– Remote control (tendency control) system in connection with the check weigher for automatic weight adjustment;

– Interface signal exchange for no box/pouch no fill;

– Interface signal exchange for sequential start and stop of the dosing unit.