ISO 22000; CLAUSE 4

Food safety management system

4.1 General Requirements

This clause is about documenting and maintaining an effective food safety management system, and updating it when necessary.

The organization shall

- a) ensure that food safety hazards that may be reasonably expected to occur in relation to products within the scope of the system are identified, evaluated and controlled in such a manner that the products of the organization do not, directly or indirectly, harm the consumer,

- b) communicate appropriate information throughout the food chain regarding safety issues related to its products

- c) communicate information concerning development, implementation and updating of the food safety management system throughout the organization, to the extent necessary to ensure the food safety required by this International Standard

- d) evaluate periodically, and update when necessary, the food safety management system to ensure that the system reflects the organization’s activities and incorporates the most recent information on the food safety hazards subject to control.

Where an organization chooses to outsource any process that may affect end product conformity, the organization shall ensure control over such processes. Control of such outsourced processes shall be identified and documented within the food safety management system.

- Must control outsourcing

- Examples:

- Blending of ingredients by third party

- Third party cleaning and sanitation

- Pest Control

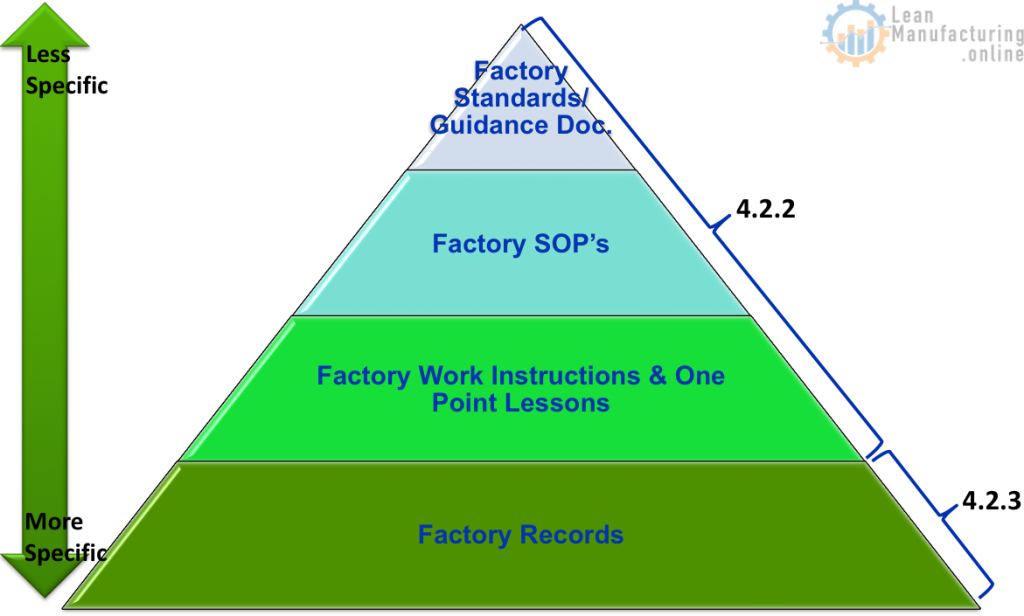

4.2.2 Control of documents

A documented procedure shall be established to define the controls needed

- a) to approve documents for adequacy prior to issue

- b) to review and update documents as necessary, and re-approve documents

- c) to ensure that changes and the current revision status of documents are identified

- d) to ensure that relevant versions of applicable documents are available at points of use

- e) to ensure that documents remain legible and readily identifiable

- f) to ensure that relevant documents of external origin are identified and their distribution controlled

- g) to prevent the unintended use of obsolete documents, and to ensure that they are suitably identified as such if they are retained for any purpose

4.2.3 Control of records

- To describe the method/procedure by which records are controlled within the Food Safety Management System, including identification, storage, protection, retrieval, retention time and disposition of records.

Documentation requirements

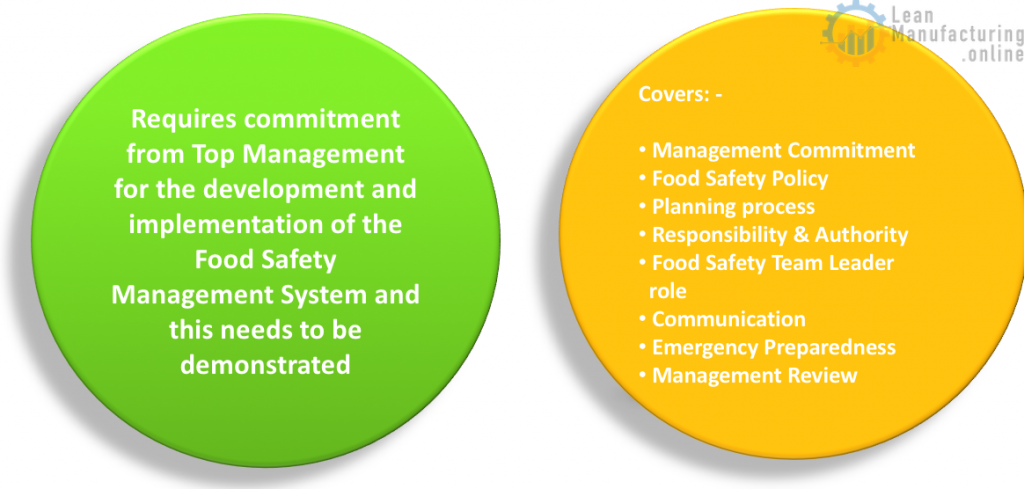

ISO 22000 Section 5 Management Responsibility

This clause is about clearly demonstrating management commitment to food safety

5.1 Management commitment

Top management shall provide evidence of its commitment to the development and implementation of the food safety management system and to continually improving its effectiveness by:

- showing food safety is supported by the business objectives of the organization,

- communicating to the organization the importance of meeting the requirements of this International Standard, any statutory and regulatory requirements, as well as customer requirements relating to food safety,

- establishing the food safety policy,

- conducting management reviews, and

- ensuring the availability of resources.

There are a number of processes/documents which can be used for showing management commitment: –

- Factory KPI’s;

- Factory food safety team support;

- Factory training & communication meetings;

- Factory FSMS improvement plan completion;

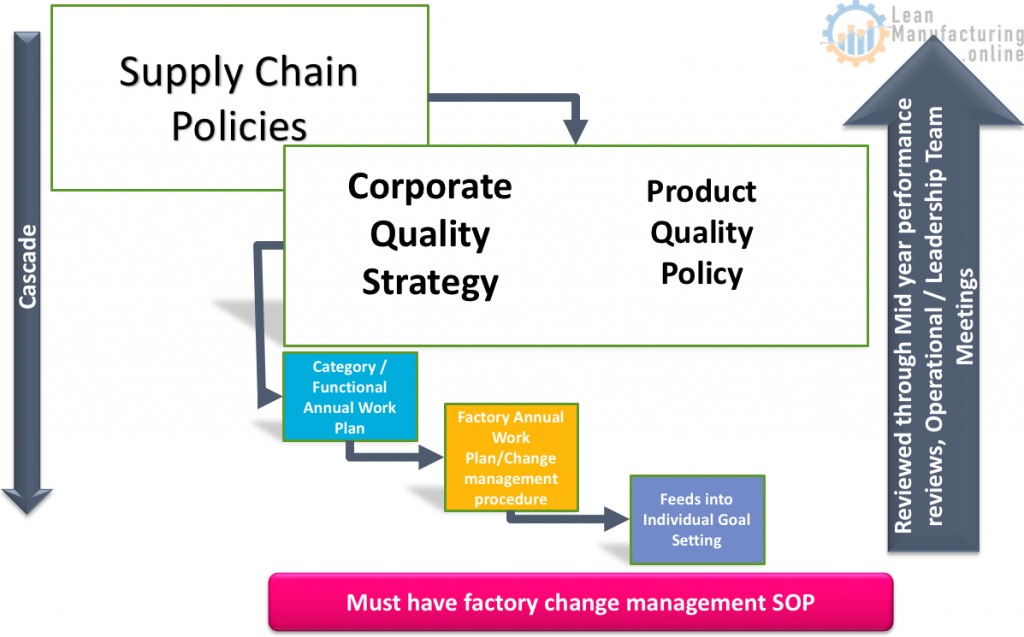

- Programs which define long term goals and are used as the basis of annual Category/Functional work plans;

- The Quality Policy which outlines the “must” and “must not” requirements which all employees must follow;

- Operational and Leadership Team Meeting Minutes – the meetings are used to review progress vs factory’s objectives and targets and help support continuous improvement.

5.2 Food safety policy

Top management shall define, document and communicate its food safety policy. Top management shall ensure that the food safety policy:

- is appropriate to the role of the organization in the food chain,

- conforms with both statutory and regulatory requirements and with mutually agreed food safety requirements of customers,

- is communicated, implemented and maintained at all levels of the organization,

- is reviewed for continued suitability (see 5.8),

- adequately addresses communication (see 5.6), and

- is supported by measurable objectives.

Factories need to ensure they use the Corporate Quality Policy, co-signed by the most senior person on their site, and ensure it is communicated to all site employees:

- It should be signed by the factory supply leader.

- It should be displayed where all employees can review it.

- It should be reviewed during employee training.

5.3 Food safety management system planning

Top management shall ensure that:

- planning of the food safety management system is carried out to meet requirements given in 4.1 as well as the objectives of the organization that support food safety, and

- the integrity of the food safety management system is maintained when changes to the food safety management system are planned and implemented.

5.4 Responsibility and authority

Top management shall ensure that responsibilities and authorities are defined and communicated within the organization to ensure the effective operation and maintenance of the food safety management system. All personnel shall have responsibility to report problems with the food safety management system to identified person(s). Designated personnel shall have defined responsibility and authority to initiate and record actions.

Role profiles, clearly defining responsibility and authority, in place for all members of the factory who have an impact on food safety:

- Factory level job descriptions and relevant training requirements are needed;

- Job descriptions must include responsibility to report problems with food safety management systems.

In addition, any standards/procedures/work instructions defined locally must include responsibility and authority for key processes/activities which have an impact on food safety.

5.5 Food safety team leader

Top management shall appoint a food safety team leader who, irrespective of other responsibilities, shall have the responsibility and authority

- to manage a food safety team (see 7.3.2) and organize its work,

- to ensure relevant training and education of the food safety team members (see 6.2.1),

- to ensure that the food safety management system is established, implemented, maintained and updated, and

- to report to the organization’s top management on the effectiveness and suitability of the food safety management system.

NOTE: The responsibility of the food safety team leader may include liaison with external parties on matters relating to the food safety management system.

Your local factory team responsible for:

- Scheduling certification activities with DNV

- Leading FSSC22000 implementation at their site

- Leading the food safety team

- Drives FSMS continuous improvement

- Reporting to factory leadership team regarding FSMS effectiveness

- Leading the internal audit program

- May be the same as the HACCP team leader

- Leads food safety & FSSC22000 training at the factory

5.6 Communication

- Effective communication, both internally and externally, is an

important part of an FSMS; - Within your business, some internal/external communication channels are already defined/available, find them through your intranet or SharePoint.

- However, there will be additional local internal / external communication channels which need to be defined, as appropriate, at factory level: –

- External (e.g. enquiries, complaints, contracts, meetings, visits etc);

- Statutory and Regulatory authorities within the country the factory is operating;

- Customer requirements;

- Suppliers and contractors;

- Other organizations who might have an impact on or be impacted by the effectiveness of the FSMS;

- Internal;

- Any changes / feedback that has an impact on the FSMS (e.g. Materials, Equipment, Product, People, Statutory / Regulatory, customer, complaints etc) (Change management procedure must include requirements of 5.6.2);

- Food Safety team meeting Minutes;

- Management Review.

Records must be kept of communications that have been made, both internally and externally

5.6.1 External communication

To ensure that sufficient information on issues concerning food safety is available throughout the food chain, the organization shall establish, implement and maintain effective arrangements for communicating with

- suppliers and contractors,

- customers or consumers, in particular in relation to product information (including instructions regarding intended use, specific storage requirements and, as appropriate, shelf life), enquiries, contracts or order handling including amendments, and customer feedback including customer complaints,

- statutory and regulatory authorities, and

- other organizations that have an impact on, or will be affected by, the effectiveness or updating of the food safety management system.

Such communication shall provide information on food safety aspects of the organization’s products that may be relevant to other organizations in the food chain. This applies especially to known food safety hazards that need

to be controlled by other organizations in the food chain. Records of communications shall be maintained.

Food safety requirements from statutory and regulatory authorities and customers shall be available.

Designated personnel shall have defined responsibility and authority to communicate externally any information concerning food safety. Information obtained through external communication shall be included as input to system updating (see 8.5.2) and management review (see 5.8.2).

5.6.2 Internal communication

The organization shall establish, implement and maintain effective arrangements for communicating with

personnel on issues having an impact on food safety.

In order to maintain the effectiveness of the food safety management system, the organization shall ensure that

the food safety team is informed in a timely manner of changes, including but not limited to the following:

- products or new products;

- raw materials, ingredients and services;

- production systems and equipment;

- production premises, location of equipment, surrounding environment;

- cleaning and sanitation programmes;

- packaging, storage and distribution systems;

- personnel qualification levels and/or allocation of responsibilities and authorizations;

- statutory and regulatory requirements;

- knowledge regarding food safety hazards and control measures;

- customer, sector and other requirements that the organization observes;

- relevant enquiries from external interested parties;

- complaints indicating food safety hazards associated with the product;

- other conditions that have an impact on food safety.

The food safety team shall ensure that this information is included in the updating of the food safety

management system (see 8.5.2). Top management shall ensure that relevant information is included as input to the management review (see 5.8.2).

5.7 Emergency preparedness and response

Top management shall establish, implement and maintain procedures to manage potential emergency situations and accidents that can impact food safety and which are relevant to the role of the organization in the food chain.

The emergency response procedure must include procedures for assuring food safety in the event of an emergency. For example procedures for assessing the safety of refrigerated food materials in the event of a power outage.

- Factory emergency response procedure must be developed

- Examples of issues

- Power outage;

- Floods;

- Fire;

- Severe weather;

- Earthquake.

- Examples of issues

5.8 Management review

5.8.1 General

Top management shall review the organization’s food safety management system at planned intervals to ensure its continuing suitability, adequacy and effectiveness. This review shall include assessing opportunities for improvement and the need for change to the food safety management system, including the food safety policy. Records of management reviews shall be maintained (see 4.2.3).

5.8.2 Review input

The input to management review shall include, but is not limited to, information on

- follow-up actions from previous management reviews,

- analysis of results of verification activities (see 8.4.3),

- changing circumstances that can affect food safety (see 5.6.2),

- emergency situations, accidents (see 5.7) and withdrawals (see 7.10.4),

- reviewing results of system-updating activities (see 8.5.2),

- review of communication activities, including customer feedback (see 5.6.1), and

- external audits or inspections.

NOTE The term “withdrawal” includes recall.

The data shall be presented in a manner that enables top management to relate the information to stated objectives of the food safety management system.

5.8.3 Review output

The output from the management review shall include decisions and actions related to:

- assurance of food safety (see 4.1),

- improvement of the effectiveness of the food safety management system (see 8.5),

- resource needs (see 6.1), and

- revisions of the organization’s food safety policy and related objectives (see 5.2).

- This is a critical activity for implementation/maintenance of an FSMS as it shows:

- Management commitment to the FSMS;

- Continuous improvement of the FSMS, making sure it still meets the requirements of the factory;

- Changes / updates that are needed to policy, objectives and targets;

- Management reviews must be conducted at least annually (preferably 6 monthly);

- Minutes must be kept of these meetings as it will record all of the actions/decisions taken related to the FSMS.

Management reviews may be conducted during leadership team meetings. Records of management review meetings must include copies of the documents reviewed and records of decisions made and actions taken.

- Factories already have daily/weekly/monthly operational and leadership team meetings;

- The suggested approach is to use one / two of the monthly leadership team meetings as an opportunity to carry out the management review;

- The food safety team leader should provide the material to be reviewed.

This meeting should include (but is not limited to):