PM Element 5. LUBRICATION PLAN

Step 1

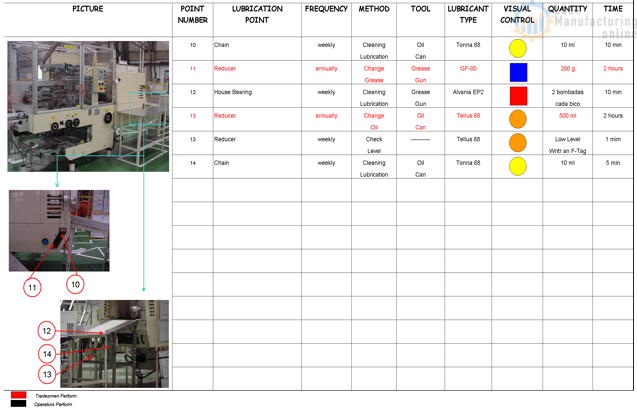

Identify the component that needs to be lubricated.

Step 2

Determine the right type of lubricant.

Step 3

Determine the right method and tools to perform lubrication.

Step 4

Determine the right frequency. Daily, weekly, monthly, quarterly.

Step 5

Identify if downtime is necessary to perform lubrication. If downtime is needed, how much time is required?

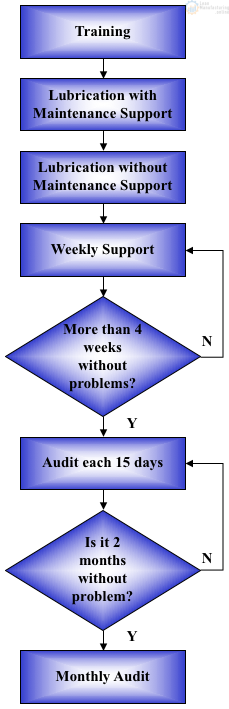

During AM Step 3 train the operators to perform Autonomous Lubrication.

- Perform the first autonomous lubrication with maintenance support.

- When operators start to perform lubrication alone, implement an audit system to monitor the efficiency of the training.

The next Flow Chart describes the process.

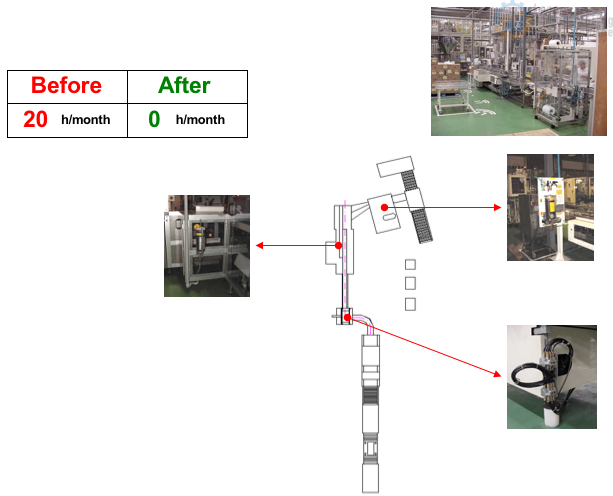

No Stop Lubrication

No Stop Lubrication means that all lubrication is performed while the line is running.

After completing the lubrication standard start the studies to reduce the lubrication downtime to zero. To make this possible:

- Central Automatic Lubrication,

- Manual Pumps,

- Centralize Zerk Fittings.