A breakdown is a loss of or reduction in a machine’s capacity to function. Breakdown loss is the time losses (reduction in output) and physical losses (increase in defectives and rework) arising from sporadic or chronic failures.

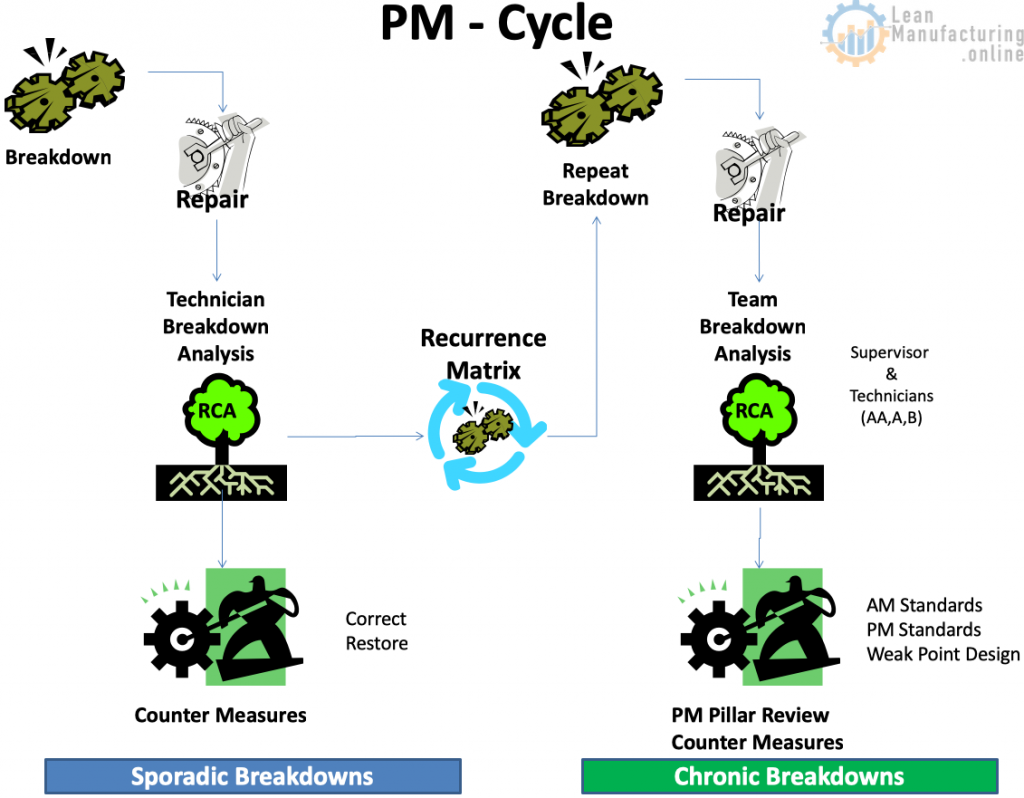

Let’s review PM cycle step-by-step:

- Breakdown occurs, maintenance crew is called to repair machine and return back to production or sanitation crew (if food surfaces were touched and/or machine lost sterility);

- Maintenance technician performs Breakdown Analysis;

- All information about breakdown is captured in Recurrence Matrix;

- Countermeasures or correct restore implemented to prevent breakdown from happening again,

- SPORADIC BREAKDOWN

Breakdown happened again!

- Of course it must be repaired;

- RCA must be performed with larger team (Maintenance technicians and Supervisor);

- Develop AM and PM standards, possibly “weak point design?)

- Restoration;

- Must be reviewed by PM pillar;

- CHRONIC BREAKDOWN

Action plan

Future Plans

- Continue to make significant reductions in plant losses – material and OEE;

- Improve the link between Focused Improvement and Quality, Effective (Planned) Maintenance, Training and Education, SHE and Autonomous Maintenance pillars, using FI tools, in order to focus on the most significant losses;

- Engage all employees to consistently use FI tools e.g. Kaizens, CAP-DO, 5 why analysis, 5W+1H;

- Increase the number of zero loss case studies;

- Expand use of best practice for visual controls and poka yoke;

- Improve process for horizontal replication of improvements;

- Expand use of advanced problem solving tools – P-M analysis, QA/QM matrix and FMEA.