All modern manufacturing facilities use principles that “all accidents are preventable,” but sometimes incidents or accidents can still happen.

Gathering as much data as possible and analyzing it to prevent a recurrence is essential.

Investigation Report

Let’s review the first part – [ Incident Reporting ] A. To be completed by the COMMUNICATOR AT THE TIME OF INCIDENT.

All fields in the report’s first part (A) are self-explanatory. Let’s review “The incident / Accident Description and Evaluations sections.

Description

Create a detailed explanation of the area/part of the equipment, what happened, and who and how – attach a diagram or picture applicable in the “Attachment” sheet only.

Evaluations

All evaluation sections must be filled to get a Hazard Rating Number (HRN), suggesting a future course of action.

Degree of Possible Harm

- 0.1 —> Scratch or bruise;

- 0.5 —> Laceration or mild ill health effect;

- 1 —> Break of a minor bone or minor temporary occupational illness;

- 2 —> Break of a major bone or minor permanent occupational illness;

- 4 —> Loss of one limb, one eye, or serious temporary occupational illness;

- 8 —> Loss of limbs, eyes, or serious permanent occupational illness;

- 15 —> Fatality.

Likelihood of Occurrence

- 0 —> Impossible cannot happen;

- 0.1 —> Almost impossible possible in extreme circumstances;

- 0.5 —> Highly unlikely though conceivable;

- 1 —> Unlikely but could occur;

- 2 —> Possible but unusual;

- 5 —> Even chance could happen;

- 8 —> Probable not surprised;

- 10 —> Likely to be expected;

- 15 —> Certain no doubt.

Frequency of Exposure

- 0.1 —> Infrequently;

- 0.2 —> Annually;

- 1 —> Monthly;

- 1.5 —> Weekly;

- 2.5 —> Daily;

- 4 —> Hourly;

- 5 —> Constantly.

Number of Personnel

- 1 —> 1-2 persons;

- 2 —> 3-7 persons;

- 4 —> 8-15 persons;

- 8 —> 16-50 persons;

- 12 —-> >50 persons.

Hazard Rating Number (HRN)

HRN = DPH * Likelihood * FOE * NOP

- HRN range 1-3, the risk is minimal – No need to make any changes;

- HRN range 3-9, the risk is still low- review existing measures;

- HRN range 10-15, the risk is medium – control measures need to be reviewed;

- HRN range 16-20, the risk is HIGH – future activity could be stopped;

- HRN higher than 25, EXTREME risk – not recommend restarting activity.

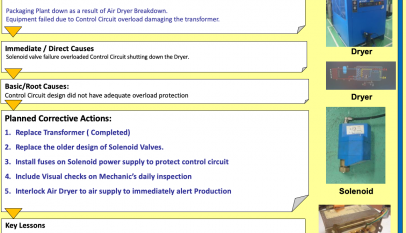

Investigation Part using Cap-Do Cycle

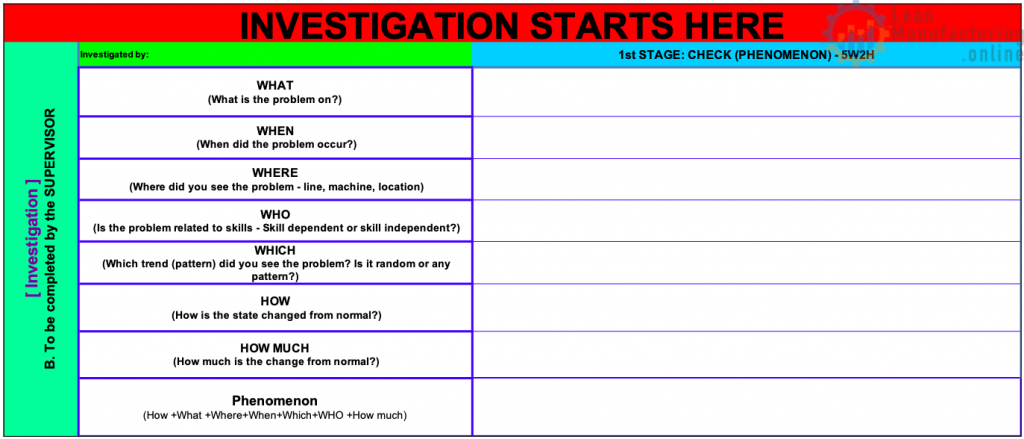

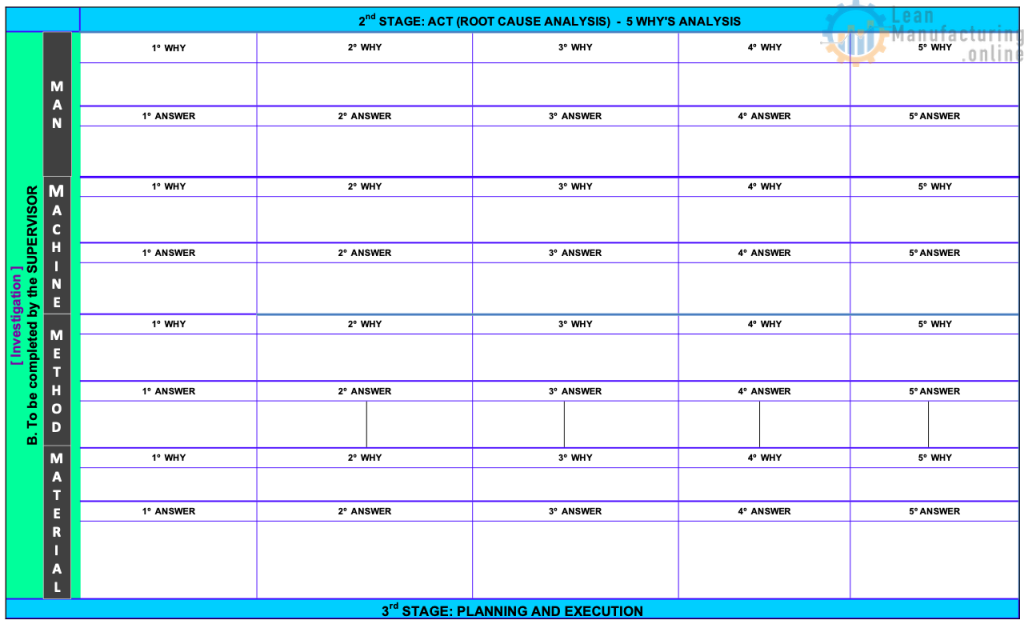

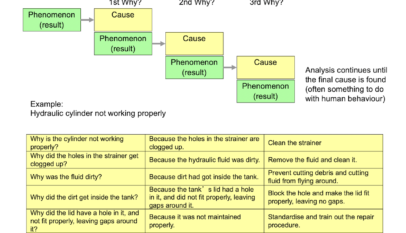

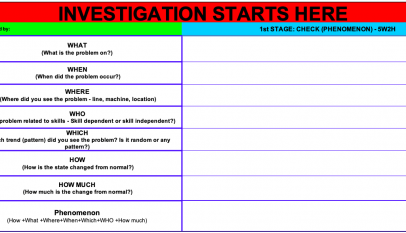

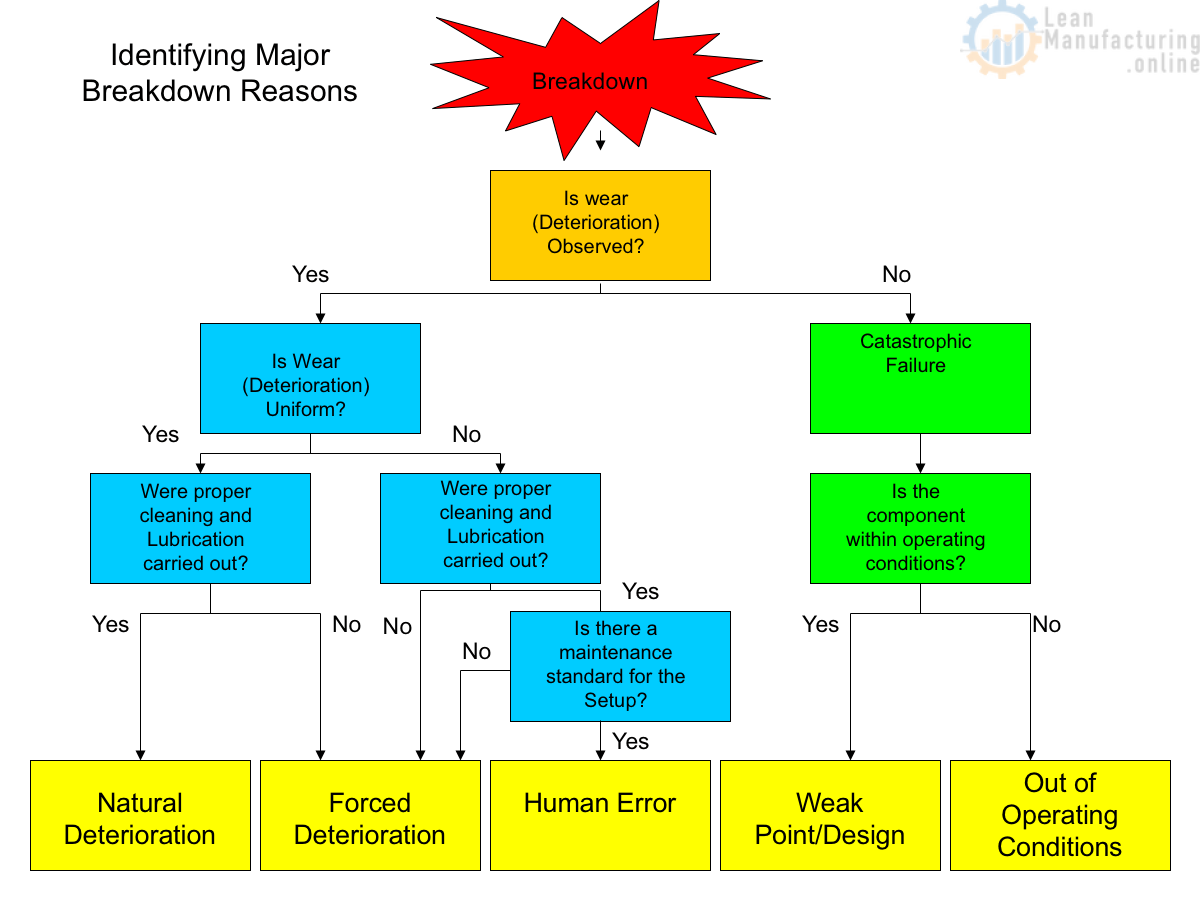

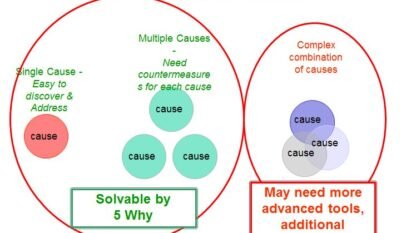

Start 1st stage of investigation by determining the phenomenon using 5W2H analysis. After it’s done, use the 2nd stage to find the root cause using a hybrid of RCA and 4M Analysis.

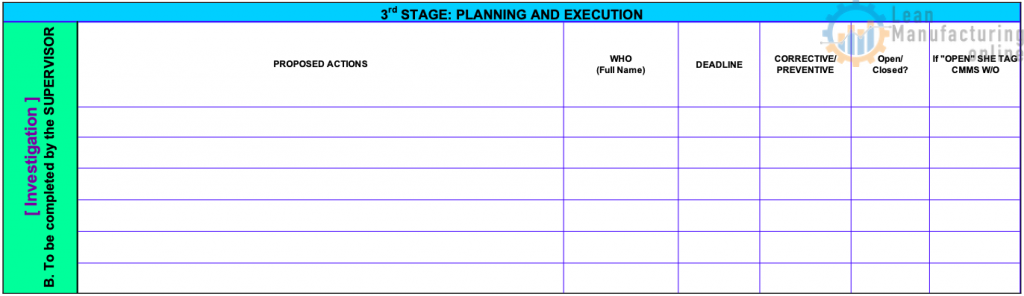

Finally, after finding a single of multiple causes, proceed to stage 3 and create an action plan of countermeasure with the assignment of the responsible person and completion timeframe.

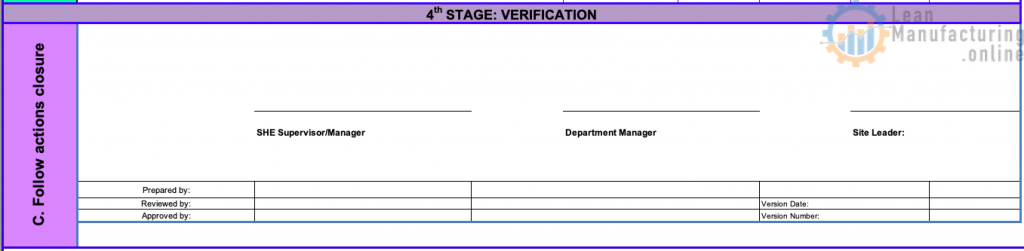

The last section is used to verify and close the Incident Report

If your company requires the template mentioned above, you can get it from our store.

I need more details