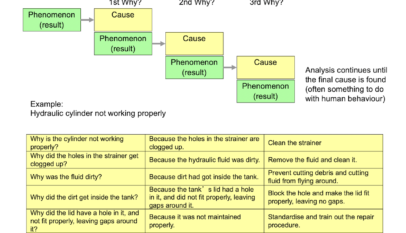

Why-Why Analysis

It is a technique for tracking down the root causes of undesirable phenomena logically and methodically, based on the facts, instead of merely brainstorming.

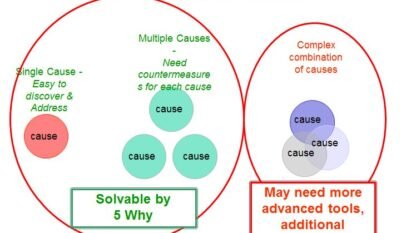

Two Approaches to Why-Why Analysis

- Approach starting from “what should have happened” – Consider the necessary conditions and list them as items to investigate. Then investigate each state on the spot to see whether it is being satisfied.

- Approach starting from first principles- Focusing on the point at which the problem occurred, go back to first principles, and do the first step of the analysis by asking why these principles failed to operate.

8 Important Considerations when Implementing Why-Why Analysis

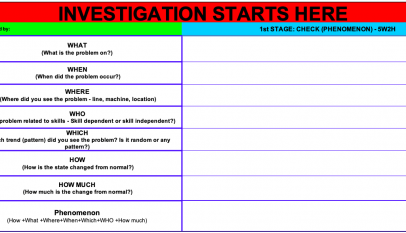

- Identify the phenomenon by closely observing the physical objects and materials involved.

- When defining the phenomenon and answering the Whys, use simple phrases like ‘A did/became B’ when explaining the phenomenon and answering the Whys.

- Check the logical structure of the analysis by reading back from the last Why? to the phenomenon.

- Reading the analysis backward, check that all the possible causes have been identified for each event.

- Continue asking Why? until you identify the actions preventing the problem from recurring.

- Only note items that deviate from the standard.

- Avoid trying to identify causes lying in human psychology.

- Do not use negative words such as ‘bad.’

Why-Why Analysis Example

The Anatomy of Why-Why Analysis

- Ascertain the facts regarding the problem

- Investigate the facts in detail, examining the problem’s location and the physical objects in which it manifested itself.

- Understand the role played (the function fulfilled) by the mechanism or structure involved

- For a piece of equipment: Sketch the affected section of the equipment and related parts.

- For a task: Determine the procedure, sequence, main features and role of the task.

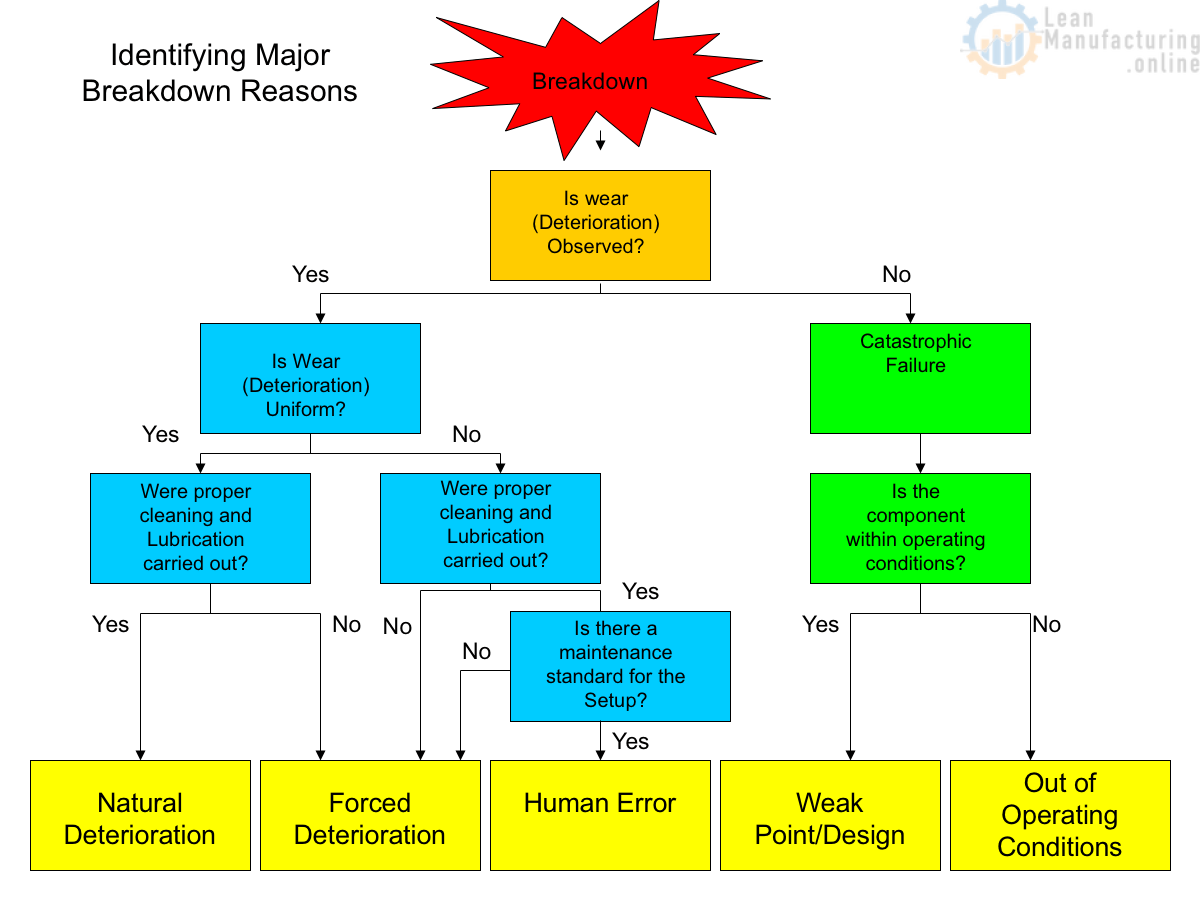

- Decide on which Why-Why Analysis approach to use

- Sporadic, isolated problems: Start from the viewpoint of what should have happened (but didn’t).

- Chronic, recurrent problems: Start from first principles.

- Carry out the Why-Why Analysis

- When starting from “what should have happened,” think about the necessary conditions (the conditions that must be satisfied for everything to work as it ought to), and list them up as items to investigate. Then investigate each condition on the spot to see whether it is being satisfied (if a condition is found to be OK, eliminate it from the investigation).

- When starting from first principles: Focusing on the point at which the problem occurred, go back to first principles, and do the first step of the analysis by asking why these principles failed to operate. Then continue the analysis, checking the evidence at each step.

- Decide what investigation techniques to use.

- When you arrive at the final ‘because,’ decide how you will verify it.

- Decide on the verdict (OK or not)

- Look at the final ‘because,’ compare it with how things should be, and decide whether the current state of affairs is OK.

- Formulate and implement Improvement

- Formulate improvements to correct items that are not OK, and then implement them.

Why-why analysis can solve many problems, including technical, organizational, and process-related problems. It is often used in quality improvement efforts and is a vital tool in the Six Sigma methodology.