Quality Management Systems

Mastering Acceptance Quality Level (AQL): A Practical Guide

Acceptance Quality Level (AQL) is a widely used quality control tool that helps manufacturers and suppliers strike the right balance between product quality and inspection efficiency. This guide explains what AQL is, how it works, its sampling process, inspection levels, and when to use it effectively.

Read More »What Quality Leaders Often Overlook: The Critical Role of Problem Solving

Quality systems often emphasize prevention and inspection, but without a structured problem-solving strategy, organizations risk recurring failures and massive losses. Discover why making problem solving a core pillar can transform your operational performance.

Read More »Mastering the Supplier Quality Audit: A Practical Guide

A strong supplier relationship starts with a structured audit. This guide breaks down each section of a professional Supplier Quality Audit Sheet—showing you what to look for, what to ask, and what evidence to expect.

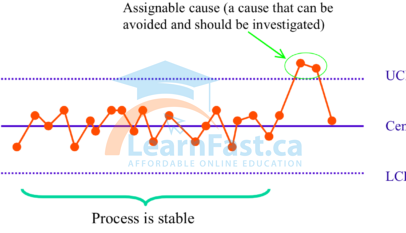

Read More »How to Read SPC Control Charts Like a Pro

Unlock the power of process stability using Nelson's 8 Rules for SPC Control Charts. Learn how to detect shifts, trends, and variations before they become costly problems. Perfect for Lean Six Sigma professionals, engineers, and quality teams.

Read More »