Safety, Health and Environment

Understanding Unsafe Acts: Definitions, Dangers, and Prevention Measures

In this blog post, we will cover the fundamental aspects of safety, which include identifying unsafe conditions, unsafe actions, near misses, and accidents. It emphasizes the significance of acknowledging and managing potential hazards while emphasizing the importance of following safety protocols, using personal protective equipment, and adopting a safety-conscious culture.…

Read More »TPM Pillar Self Assessment

5S Autonomous Maintenance Early Equipment Management Education and Training Focused Improvement Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM World Class Manufacturing

The TPM Self Assessment’s purpose is to provide information to assist in running the factory. By showing the strengths and weaknesses of each TPM pillar using a structured approach.

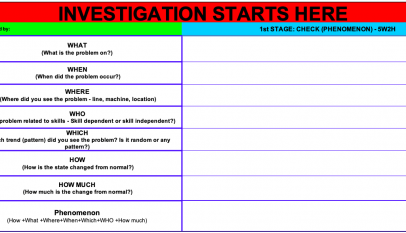

Read More »Safety, Health and Environment Investigation Report and Analysis

5 Why Analysis Blog Cap-Do Lean Six Sigma PM-analysis Root Cause Analysis Safety Safety, Health and Environment TPM

All modern manufacturing facilities use principles that “all accidents are preventable,” but sometimes incidents or accidents can still happen. Gathering as much data as possible and analyzing it to prevent a recurrence is essential. Investigation Report Let’s review the first part – [ Incident Reporting ] A. To be completed…

Read More »The five steps towards visible Health and Safety Leadership

One Point Lessons are short visual presentations on a single point that sharpen job-related knowledge, easily share important information just-in-time Improve skills by communicating information about specific problems and improvements Spot check forklifts, hoists, and onsite permit to work – at least one/shift. Employees will see that you are engaged.…

Read More »