Templates

Capdo form tracking – Check Analyze Plan Do

Ready to start your own Focused Improvement Project? CAP-Do will be a fast and efficient approach to achieving KPIs and targets. To capture and track the progress, you will need a CAP-Do template. The template can be downloaded here If you require one in Excel spreadsheet format, don’t hesitate to…

Read More »OPL – One Point Lesson Template – Free Download

One Point Lesson is a tool to convey information. Designed to enhance knowledge and skills in a short time, at the right time, whenever needed. To upgrade levels of expertise by having individuals study, learn and then train others in the knowledge or skill. One Point Lesson – Portrait Template…

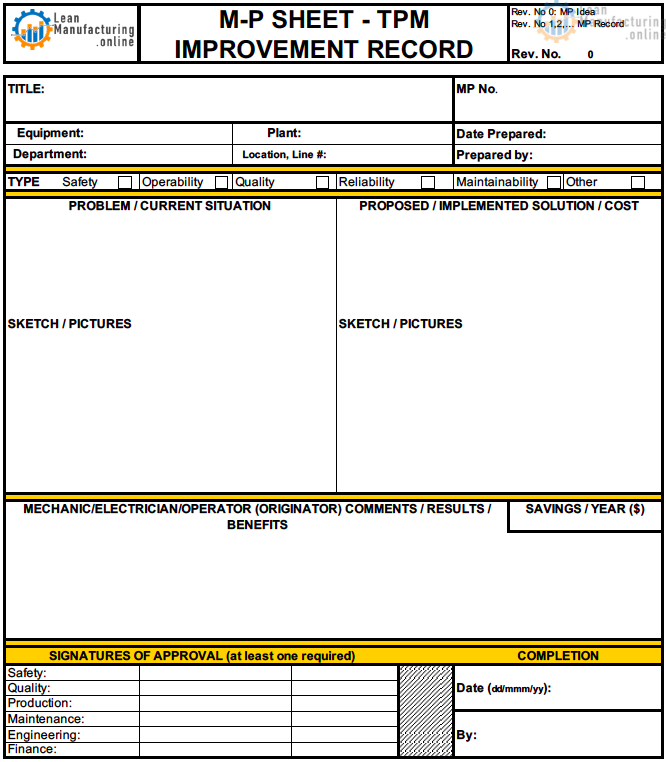

Read More »M-P sheet (EEM) free template download

The use of the latest maintenance data and technology when planning or building new equipment to promote greater reliability, maintainability, economy, operability and safety while minimizing maintenance costs and deterioration related loss. We offer free downloadable template in pdf format, to download, please click here Some of Early Equipment Management…

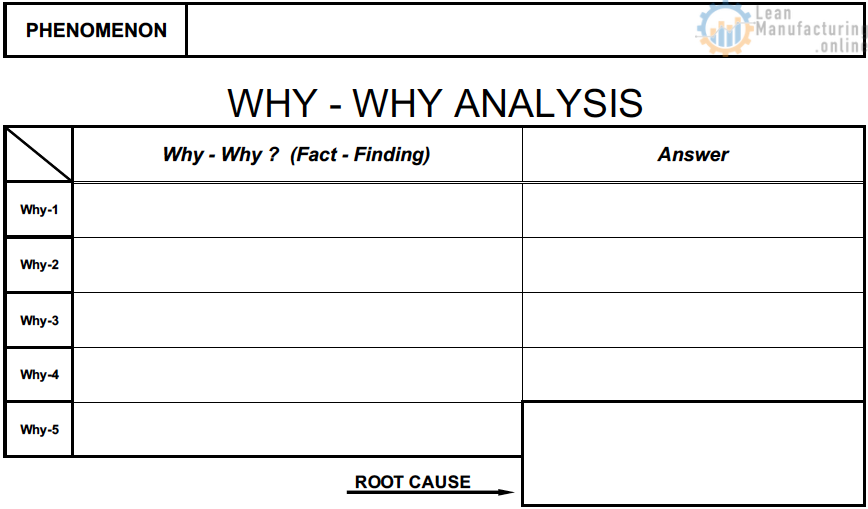

Read More »5W 1H Templates and Why-Why Analysis

In business and project management, effective tools for problem-solving and root-cause analysis are essential. This is where 5W 1H templates and Why-Why analysis come into play. These tools help individuals and teams to identify problems, understand the causes, and implement solutions in a structured and efficient manner. What is why-why…

Read More »