Change Management

The Courage to Transform: The Role of Leadership in Business Transformation

Leaders are essential in achieving successful business transformation in today's constantly changing world. They can do this by identifying the causes of transformation failures and promoting a culture based on trust, collaboration, and innovation. Committed leaders can overcome challenges in strategy development and execution, empowering their organizations to flourish in…

Read More »Tools and Techniques for Focused Improvement

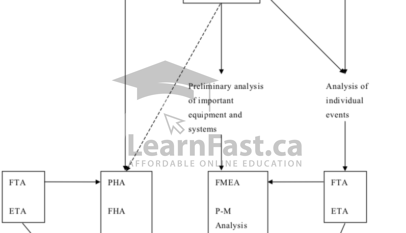

In-house failure date (MTBFs), manufacturers’ data, test data, and other data for predicting the reliability of machinery, apparatus, components, behaviours, etc., are helpful for performing internal forecasting reviews on equipment.

Read More »TPM 3 Levels – path to World-Class Manufacturing

5S Autonomous Maintenance Blog Change Management Early Equipment Management Early Product Management Education and Training Focused Improvement Instructor Training Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM TPM Introduction World Class Manufacturing

Getting to Level 3 of Total Productive Maintenance will require a LOT OF hard work, but it’s doable. Listed below is a 20-Step process on how to get there, steps 1-12 are part of Level 1 (Excellent Factory), steps 13-17 – Level 2 (Excellent Supply Chain) and finally, steps 18-20…

Read More »Team Working in TPM

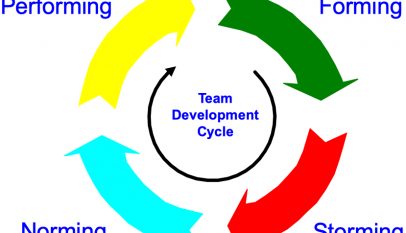

Why are we interested in Team Working? Restructuring the Workplace Fewer levels of hierarchyMore demandsLess timeNo room for empty jobsNo room for empty bossesGreater need for skilled workforceTrue productivity True Productivity Means… More TeamworkMore brainsLess stupidity TPM provides : “WHAT TO DO” Team Working provides: ”THE WAY TO DO IT”…

Read More »