FMEA

Application of FMEA for Root Cause Analysis

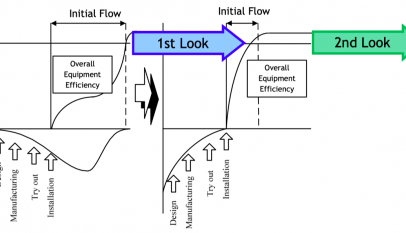

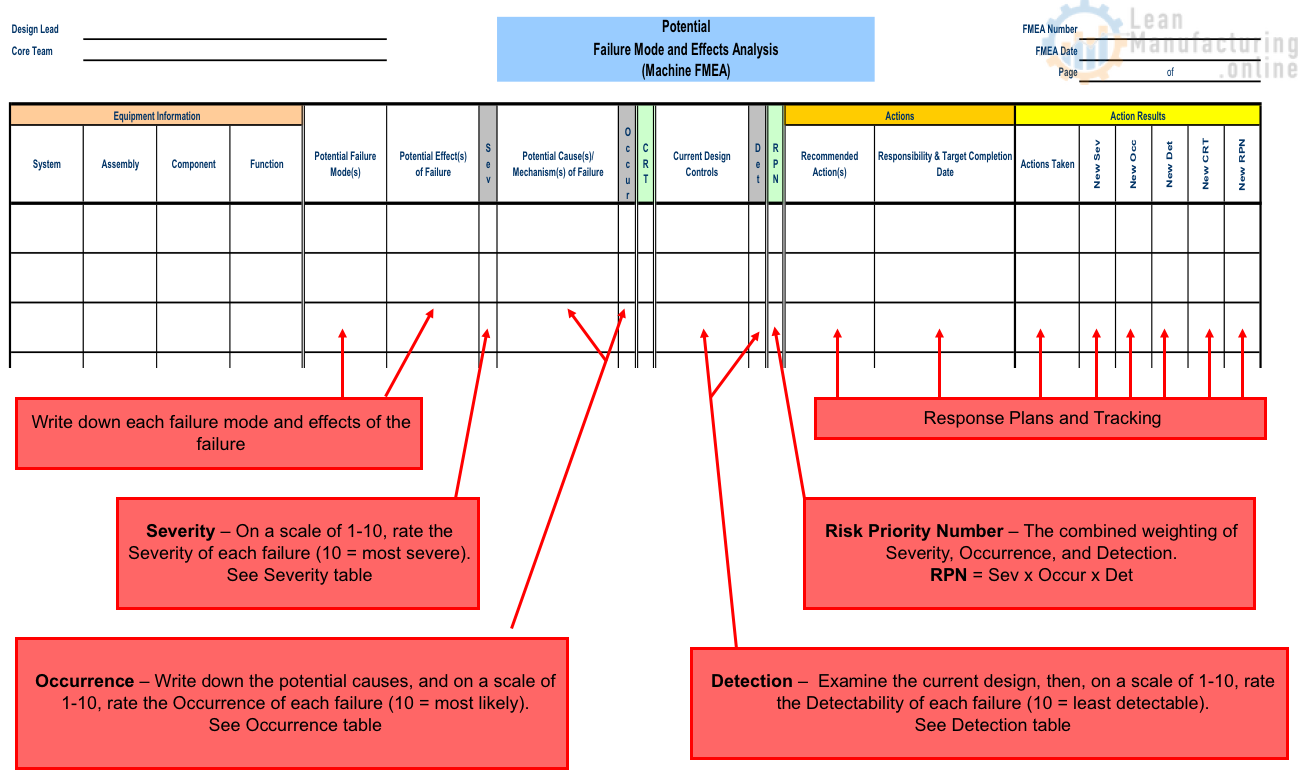

Failure Modes and Effects Analysis (FMEA) is one of the most effective analytic tools (methodology) to identify Potential Factors in a system, which is: Product or Design – to achieve the desired Quality Work System – Process Safety and Operational Efficiency Machine – Equipment Reliability and Maintainability, as well as…

Read More »Failure Mode and Effects Analysis

We should be able to determine whether we need to put detection in place in certain areas and determine how to recover from certain fault conditions.

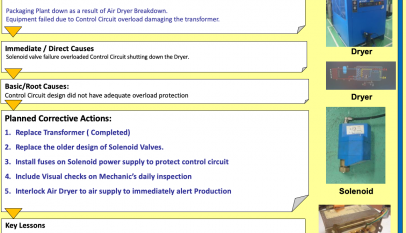

Read More »Lessons Learnt as a communication tool

Another great tool to create short but meaningful communication is Lessons Learnt. It can be used to communicate Safety, Quality or Productivity issues to all Team Members. Goal is to explain what happened and how to avoid it from happening in the future. Lessons Learnt Principles applied are to: Take…

Read More »DMAIC

DMAIC is a widely used problem-solving methodology for Define, Measure, Analyze, Improve, and Control. This methodology is commonly applied in Six Sigma projects and is designed to provide a structured approach to identifying and eliminating process defects. Each phase of the DMAIC process involves specific activities and tools that help…

Read More »