Kaizen

Kaizen Event Planning in 7 Simple Steps

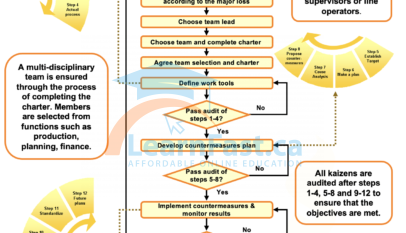

Kaizen events are a powerful tool for organizations looking to improve their processes and achieve continuous improvement. When planning and executing a successful kaizen event, it is essential to follow a systematic approach that involves defining the problem and goal, identifying the team, developing an agenda, preparing the team, conducting…

Read More »Uncovering the Secrets of Kaizen Events: What You Need to Know!

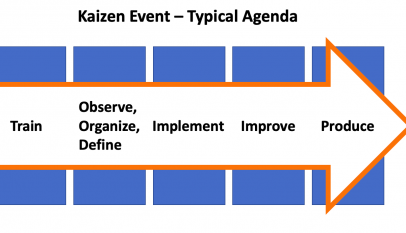

A kaizen event, also known as a kaizen blitz, is a focused improvement effort that involves a team of workers working together to identify and eliminate waste or improve processes within a specific area of a business over a short period of time, typically one to three days.

Read More »Total Productive Maintenance and case on a stand-alone machine

In this article, I will briefly touch on the TPM concept and then describe how I used the elements; what I later learned through a TPS training by Toyota Engineering Corporation (TEC) was actually Equipment Kaizen. Anyway, we made the improvements through a Kaizen Event in 5 days, and it…

Read More »Kaizen Process

Kaizen is the critical tool for executing Continuous Improvement.

Read More »