Tools

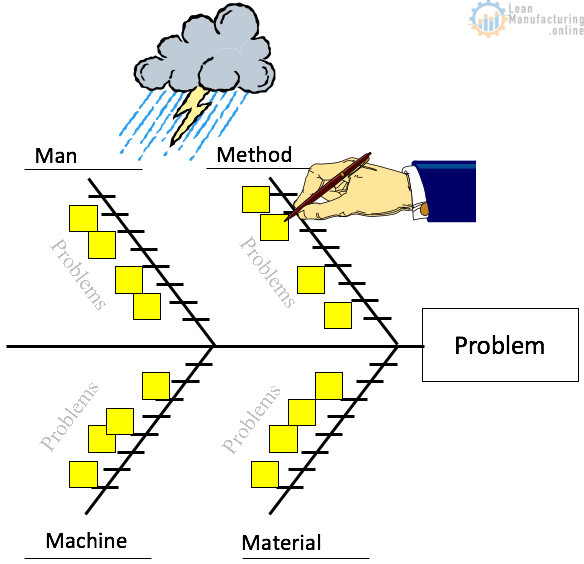

The Fishbone Diagram

What is a Fishbone Diagram? A Fishbone Diagram is a “Cause and Effect” diagram. The importance of the FBD is that it uses visual power to highlight the problems and the relationship between problems and their potential sources. When to use a Fishbone Diagram? When a simple approach is needed…

Read More »Avoiding OKR Mistakes and Misapplications

Navigating the OKR journey can sometimes be challenging. In the quest to effectively leverage Objectives and Key Results (OKRs), organizations can often encounter pitfalls and missteps. Our guide, "Avoiding OKR Mistakes and Misapplications," provides insights into common errors in OKR implementation and application. It offers practical strategies to sidestep these…

Read More »Kaizen Event Planning in 7 Simple Steps

Kaizen events are a powerful tool for organizations looking to improve their processes and achieve continuous improvement. When planning and executing a successful kaizen event, it is essential to follow a systematic approach that involves defining the problem and goal, identifying the team, developing an agenda, preparing the team, conducting…

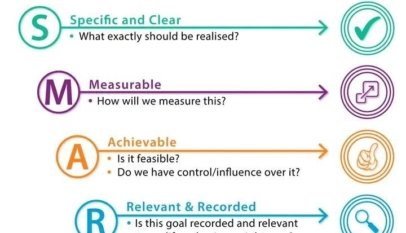

Read More »Mastering SMART Goals: A Guide to Effective Goal-Setting in Business

This indispensable guide breaks down the five key components of SMART goals - Specific, Measurable, Achievable, Relevant, and Time-bound - and provides practical examples, real-life case studies, and actionable strategies to help businesses transform their vision into reality. With its step-by-step approach, this book is your go-to resource for mastering…

Read More »