Focused Improvement

TPM Pillar Self Assessment

5S Autonomous Maintenance Early Equipment Management Education and Training Focused Improvement Manufacturing Support Planned Maintenance Quality Safety, Health and Environment TPM World Class Manufacturing

The TPM Self Assessment’s purpose is to provide information to assist in running the factory. By showing the strengths and weaknesses of each TPM pillar using a structured approach.

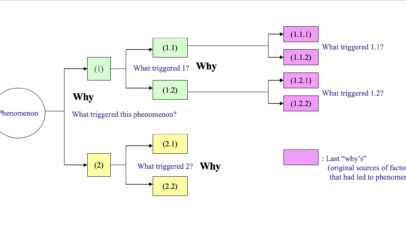

Read More »Focused Improvement. Why-why Analysis

Role of Why-Why Analysis in TPM

Read More »The 3 Tools of TPM

Autonomous Maintenance Focused Improvement Planned Maintenance Quality Safety, Health and Environment TPM TPM Introduction Training World Class Manufacturing

The technical facilitator will act as a liaison between the AM Pilot Team and those responsible for completing any technical work (be it mechanical, electrical, engineering, etc.). This will allow one point of (technical) contact for each team.

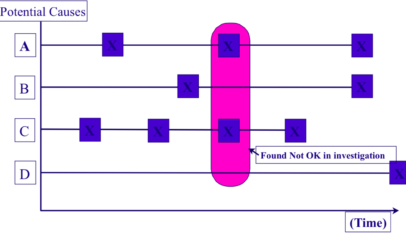

Read More »Focused Improvement – The Steps of P-M Analysis. Steps 5 – 8

Restoring something means getting it back into its original, correct condition.

Read More »