Cap-Do

Safety, Health and Environment Investigation Report and Analysis

5 Why Analysis Blog Cap-Do Lean Six Sigma PM-analysis Root Cause Analysis Safety Safety, Health and Environment TPM

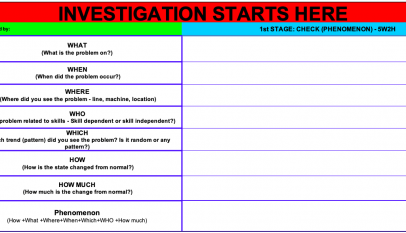

All modern manufacturing facilities use principles that “all accidents are preventable,” but sometimes incidents or accidents can still happen. Gathering as much data as possible and analyzing it to prevent a recurrence is essential. Investigation Report Let’s review the first part – [ Incident Reporting ] A. To be completed…

Read More »CAP – Do Cycle

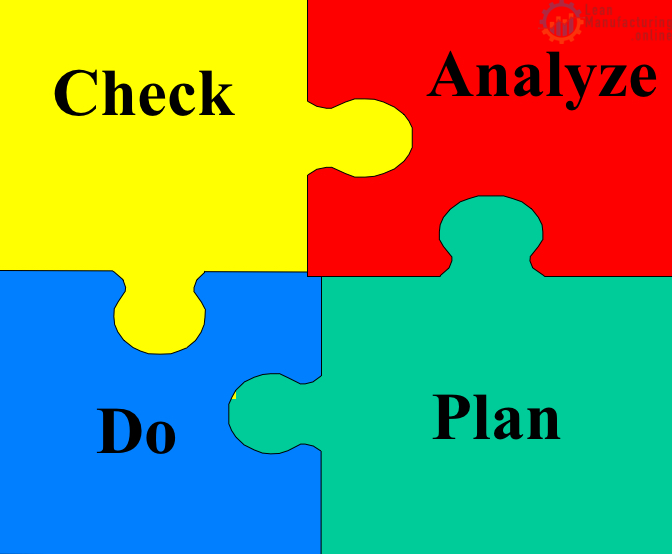

Alternative version of PDCA methodology, explaining process improvement cycle.

Read More »5 WHY Analysis, a TPM Tool for Root Cause Analysis (RCA)

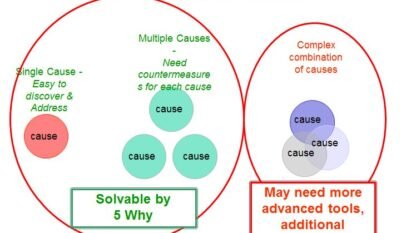

Section 1 5 WHY Process Causes of Losses are Often Complicated: Common Failure scenario: 1. Management system breakdown2. Failure to implement countermeasures3. Premature equipment failure4. Employees fail to follow the procedure5. Failure to ID & Respond6. Large Loss Results 5 Why Analysis is Proactive Addresses the Underlying Causes of Losses:…

Read More »Capdo form tracking – Check Analyze Plan Do

Ready to start your own Focused Improvement Project? CAP-Do will be a fast and efficient approach to achieving KPIs and targets. To capture and track the progress, you will need a CAP-Do template. The template can be downloaded here If you require one in Excel spreadsheet format, don’t hesitate to…

Read More »