The Lean concept of identifying and eliminating waste through improved workplace organization.

A 5S approach allows you to rethink the layout of the work cell, whether front line production, storage, or office.

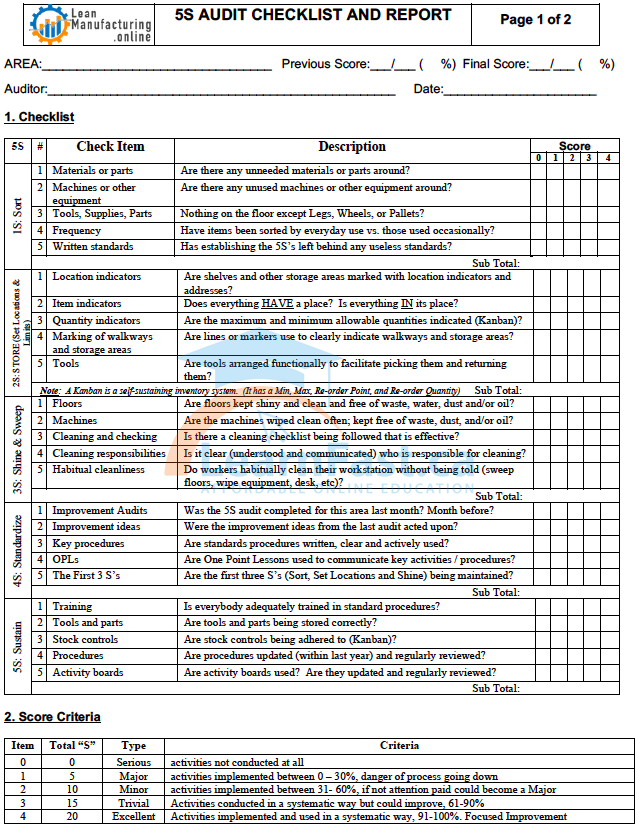

To be successful in implementing 5S (Sort, Set, Shine, Standardize, Sustain), audits must be conducted, and four simple rules must be followed:

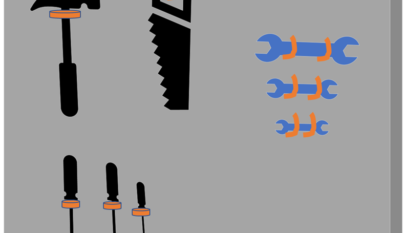

- Everything HAS a place, and everything is IN its place.

- Nothing on the Floor except Legs, Wheels, or Pallets.

- Clean to Inspect, Inspect to Detect, Detect to Correct, Correct to Perfect.

- When in doubt, throw it out.

The template can be downloaded here.