Autonomous Maintenance

Autonomous Maintenance. Let people experience success

To understand the satisfaction that Autonomous Maintenance brings, people need to experience plenty of success. This can be arranged by giving the operators every possible opportunity to get their hands dirty, find lots of equipment defects, and fix them by themselves. By correcting problems and making improvements, operators will be…

Read More »Autonomous Maintenance. Demonstrate everything on a pilot machine first

In any company, nothing will happen unless its departmental and area managers make it happen, and the Autonomous Maintenance program must likewise be led from the front. In fact, the success or failure of the program depends entirely on the leadership shown by managers. The rollout should start with a…

Read More »Autonomous Maintenance rollout plans

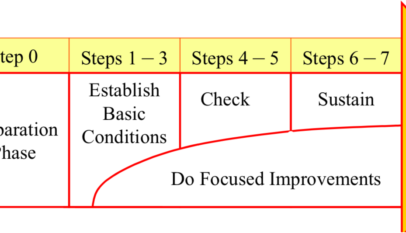

If the Autonomous Maintenance program is to be developed in a planned and structured way, then suitable approaches tailored to each equipment unit and line setup must be devised when designing the overall plan, and these individual plans must then be put into action. Figure “A Typical Autonomous Maintenance Rollout…

Read More »Autonomous Maintenance steps development example for Process Plant

Step Title Activities Equipment-Related Objectives (key points for the workplacereview)People-related Objectives (key points for team activityreview)Guidance by Management1Initial Cleaning (Cleaning is Inspection)►Eliminate dust and dirt, principally from the main body of the equipment.►Identify all minor equipment defects, contamination sources, hard-to-access areas, and sources of quality defects.►Remove all unnecessary and non-urgent items, and simplify…

Read More »