Focused Improvement

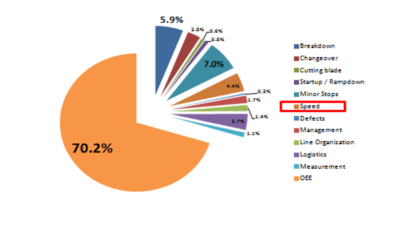

Focused Improvement – Strategies for Reducing Speed Losses

(1) Identify the true cause of the problem When attempting to raise the speed of a machine, tests should be conducted to see what kind of problems occur in practice. The speed should be raised by about 50% and items such as the following should be checked: How did the…

Read More »Focused Improvement – Some Common Issues Associated with Speed Losses

(1) Equipment specifications are unclear In some cases, owing to insufficient thoroughness at the design stage, the equipment specifications themselves are unclear and the equipment is operated too fast, resulting in quality defects and breakdowns. Sometimes the opposite happens, and the equipment is operated slower than necessary. This is particularly…

Read More »Focused Improvement – Strategies for Reducing Minor Stops

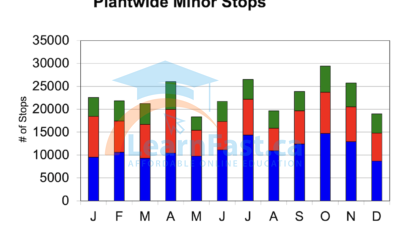

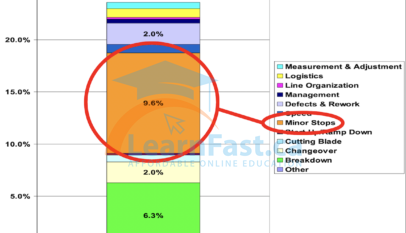

(1) Analyze phenomenon and workpiece behaviour Although the most important thing in reducing minor stops is to observe them actually happening, the opportunities for doing this are limited, making it difficult to devise precisely targeted remedial action. Phenomena should be videoed (using high-speed cameras for very fast minor stops) in…

Read More »Focused Improvement – Some Common Issues Associated with Minor Stops

(1) The losses remain hidden Minor stops may be simple and easily corrected, but the losses they generate are surprisingly large if their rate of occurrence is high or if it is a long time before they are noticed. They are often not treated as a serious problem because people…

Read More »