TPM

Focused Improvement – Strategies for Reducing Chronic Quality Defects

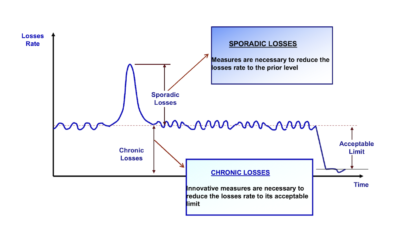

The fact that a quality defect is occurring means either that some of the causal factors that should be controlled have been overlooked, or that there are deficiencies in some of the causal factors that are being controlled.

Read More »Focused Improvement – Some Common Issues Associated with Quality Defects

When faced with a problem, we always seem to assume that there must be a definite cause and focus our efforts on finding it.

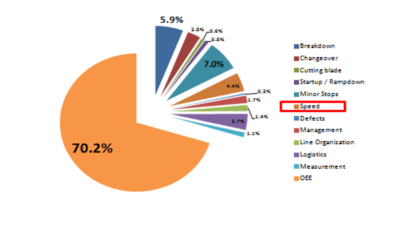

Read More »Focused Improvement – Strategies for Reducing Speed Losses

(1) Identify the true cause of the problem When attempting to raise the speed of a machine, tests should be conducted to see what kind of problems occur in practice. The speed should be raised by about 50% and items such as the following should be checked: How did the…

Read More »Focused Improvement – Some Common Issues Associated with Speed Losses

(1) Equipment specifications are unclear In some cases, owing to insufficient thoroughness at the design stage, the equipment specifications themselves are unclear and the equipment is operated too fast, resulting in quality defects and breakdowns. Sometimes the opposite happens, and the equipment is operated slower than necessary. This is particularly…

Read More »