Quality

Eliminate Flaws in 4-M Conditions and Finalize

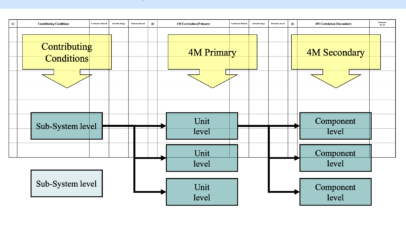

Review of 4M Conditions

Read More »Developing Quality Maintenance. Step 5 Analyze Situations where the Conditions for Building in Quality Are Unclear

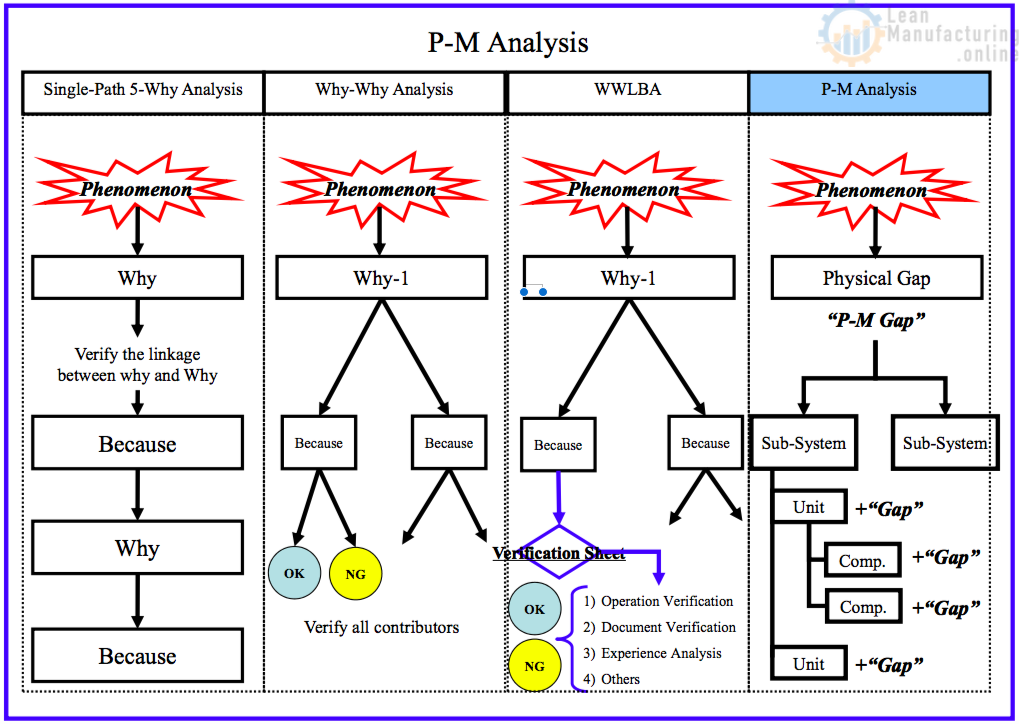

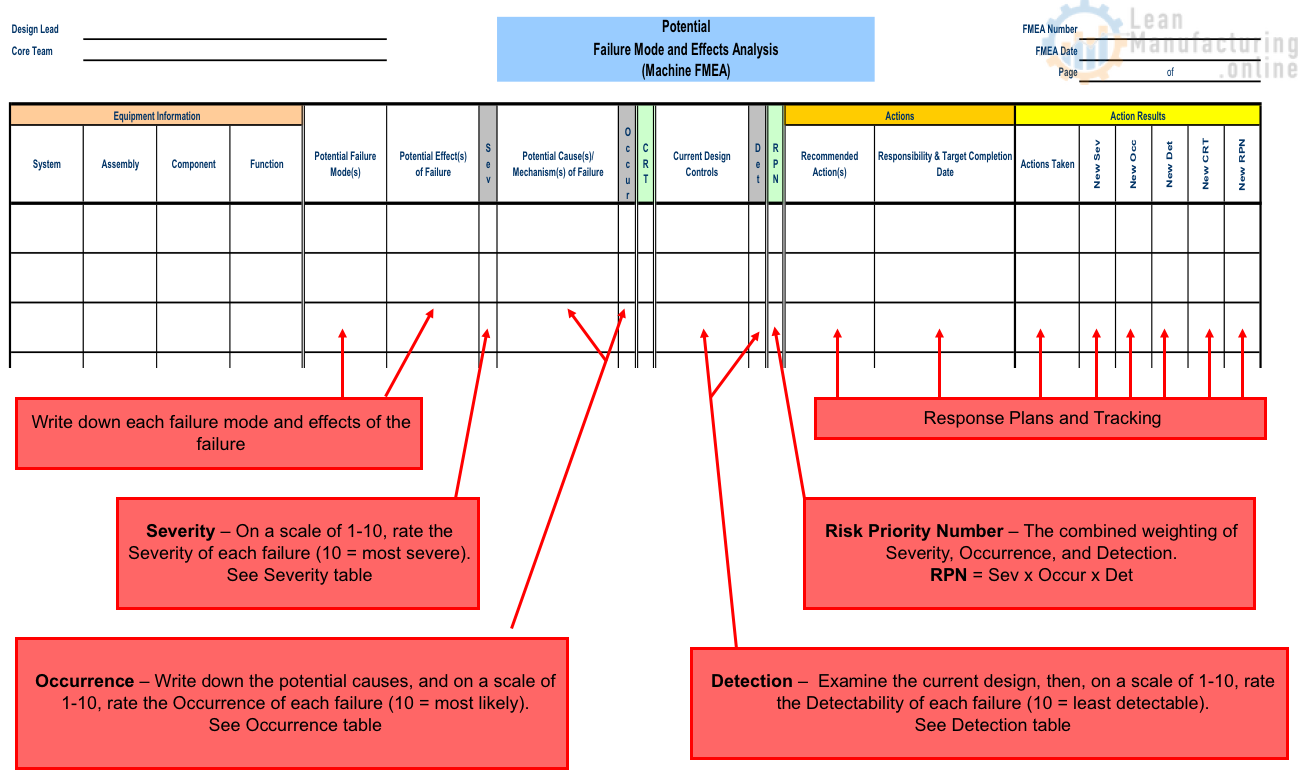

In Step 5, we employ methods such as P-M Analysis, FMEA and design of experiments, to find ways of correcting deficiencies listed in the Deficiencies Chart at Step 4 that did not seem to have an obvious solution (where the conditions required for building in quality are hard to specify).…

Read More »Developing Quality Maintenance. Step 4 Plan Action to Correct Deficiencies

Here, we identify any lapses in the 4-M conditions for each process as found in Step 3 and list them in a Deficiencies Chart. We then work out how to correct these deficiencies (see Table “Chart of Countermeasures for Deficiencies in the 4 Ms”). If the actions required to correct…

Read More »Developing Quality Maintenance. Step 2. Investigate the Processes where Defects Occur

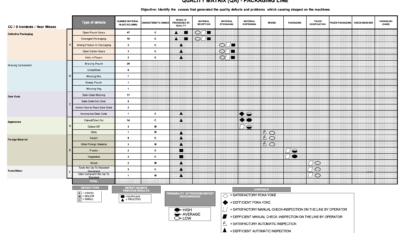

A QA matrix is a table that delineates how defects are being built into products under current conditions, in a process in which one wishes to assure quality.This matrix enables managers to see at a glance which processes are generating defects, which processes’ equipment and methods are faulty, and how…

Read More »