Blog

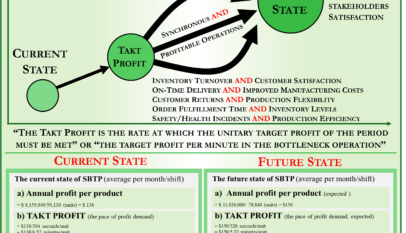

The TAKT PROFIT: The 10 “AND” Desires Unchained

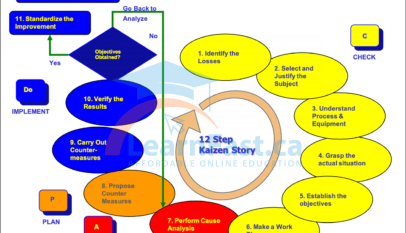

In today’s fast-paced business landscape, sustainable competitive advantage demands more than incremental improvements. Organizations must eliminate inefficiencies and maximize performance to stay ahead. Strategic KAIZEN focuses on systematic, strategic improvement to optimize operational flow. It combines managerial oversight for project selection with small group workshops for effective implementation. By continuously…

Read More »SIPOC vs COPIS: Choosing the Right Process Mapping Approach

In this post, we explore the differences between SIPOC and COPIS, two essential process mapping approaches used to understand and optimize business processes. Learn how each method focuses on different aspects of the process, depending on the customer or supplier perspective, and discover the best use cases for each.

Read More »The Strategic KAIZEN Mastery

Strategic Kaizen principles offer a roadmap for businesses to improve their efficiency and profitability by focusing on TAKT Profit. Learn how to align operations, reduce waste, and optimize workflow to achieve sustainable success.

Read More »Top Trends Shaping the Future of Management Training

With businesses evolving at a fast pace, management training needs to align with the demands of the digital age. Emphasizing digital skills, experiential learning, social responsibility, and personalized education enables managers to remain competitive. This blog delves into the key trends redefining management training and their impact on leadership in…

Read More »