Blog

The Nine Essential Skills of an Outstanding Consultant

Discover the nine essential value-added skills that every outstanding consultant should possess. These skills serve as a guide for both clients seeking to hire a consultant and for consultants looking to refine their craft. From attentive listening to practical education, learn how these qualities contribute to transformative partnerships that drive…

Read More »The Kano Analysis

The Kano method, influenced by Herzberg's 2-Dimensional Theory, provides a comprehensive approach to understanding customer satisfaction and quality management. By focusing on firsthand experiences, positive and negative quality elements, and addressing latent requirements, businesses can better meet customer needs and ensure long-term success.

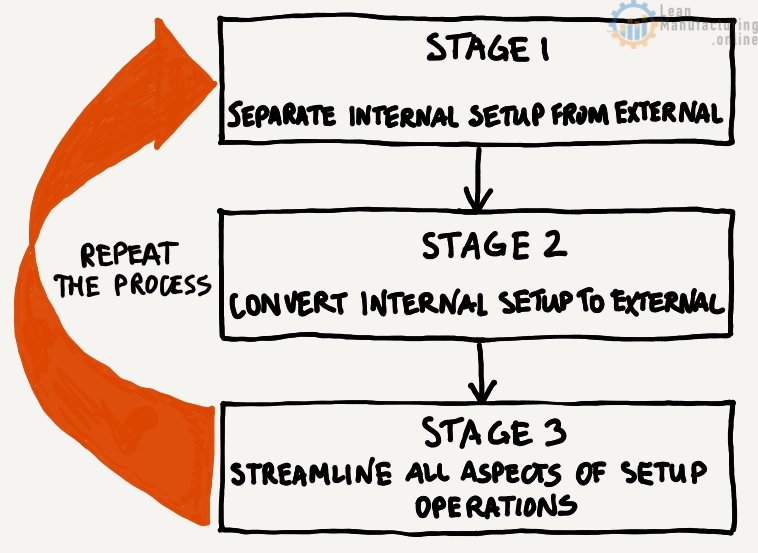

Read More »Revolutionizing Lean Manufacturing: Introducing SMED v2

Discover the revolutionary SMED v2 approach to lean manufacturing, which builds upon traditional SMED principles by incorporating advanced data analysis, digitalization, and Industry 4.0 technologies. Learn how to effectively implement SMED v2 in your organization by optimizing internal and external setup processes and enhancing verification and iteration. Stay competitive in…

Read More »The Power of Routine Quality Audits in Manufacturing: 6 Game-Changing Benefits

Discover the six game-changing benefits of routine quality audits in manufacturing, from identifying nonconformities to fostering continuous improvement and strengthening customer confidence. Embrace the power of regular audits and stay competitive in today's fast-paced market.

Read More »