Blog

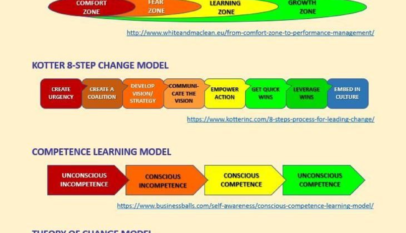

Embracing Change Management on the Manufacturing Plant Floor

Embracing change management on the plant floor is crucial for maintaining a competitive edge. By assessing the need for change, effectively communicating its benefits, providing training and support, and consistently monitoring outcomes, organizations can optimize operations, increase efficiency, and drive innovation in an ever-changing landscape.

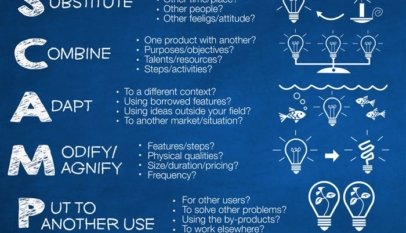

Read More »Unleashing Creativity with the SCAMPER Method: 7 Steps to Great Business Ideas

Unleash your creativity and discover innovative business ideas with the SCAMPER framework. This powerful technique guides you through seven areas of questioning—Substitute, Combine, Adapt, Modify, Put to Another Use, Eliminate, and Reverse—to transform existing products, services, or processes. By asking the right questions and embracing experimentation, you can unlock new…

Read More »Distinguishing Outcome from Output: A Comprehensive Analysis of Value Creation and Measurement in Business

This study emphasizes the importance of differentiating between outcomes and outputs in business, examining their role in value creation and measurement. By considering quantitative and binary dimensions, organizations can better understand the capabilities, flexibility, and adaptability required to achieve overarching outcomes. Additionally, refining existing metrics and developing appropriate measurement strategies…

Read More »Scrum Cheat Sheet: A Comprehensive Guide to Mastering Scrum

This comprehensive guide, based on a Scrum Cheat Sheet, covers key concepts and terminologies to help you master the Scrum framework. Learn about user stories, estimation techniques, Scrum roles, artifacts, and processes involved in Scrum, and overcome common challenges to effectively implement Scrum in your projects.

Read More »