Blog

Three simple steps for better change management

Change Management Toolkit is a valuable resource that provides a structured approach to managing change effectively in organizations. The toolkit includes templates, tools, and techniques that can be customized to meet the organization's specific needs. It focuses on preparing for change, managing change, and sustaining change. The toolkit helps organizations…

Read More »Why get a Project Management Professional (PMP®) certification?

Are you looking to boost your career in project management and stand out from the crowd? 🚀 In today’s competitive job market, acquiring a Project Management Professional (PMP®) certification could be the key to unlocking new opportunities and propelling your career to new heights. We’re excited to share our comprehensive…

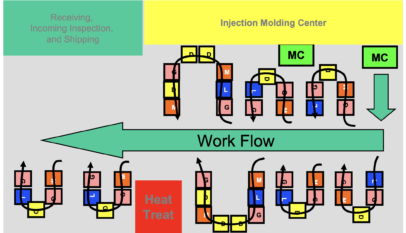

Read More »Integrating The Lean Enterprise

Lean enterprise is a business philosophy and set of practices that aim to continuously improve the efficiency and effectiveness of an organization by eliminating waste and increasing customer value. It is based on the principles of the Toyota Production System, developed at the Toyota Motor Corporation in Japan in the…

Read More »Senior Leader Best Practices

Choose to use Process Excellence projects as the mechanism for solving your critical business issues. Relentlessly communicate the importance of continuous improvement and encourage all staff to embrace the Process Excellence methodology. Choose your best people to lead projects and help them succeed. Participate in monthly project reviews. Understand the…

Read More »