Continuous Improvement

How to Use Dashboards to Drive Shop Floor Result

Dashboards are more than numbers on a screen—they are powerful tools that align teams, guide decisions, and spark improvement. Discover how to design a daily production dashboard that goes beyond reporting and becomes the heartbeat of your shop floor.

Read More »Stop Guessing OEE: A Step-by-Step Guide to Better Results

OEE isn’t just a number — it’s a roadmap for improvement. By using a standard template, you can uncover downtime, speed, and quality losses with clarity and consistency. Learn how to break down OEE step by step and transform it into a tool for real performance gains.

Read More »Daily Habits of High-Performing Leaders

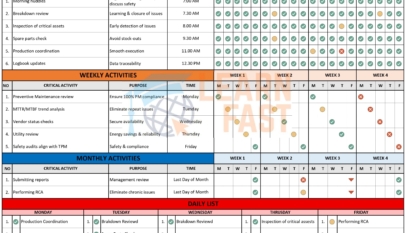

Leader Standard Work (LSW) defines the rhythm of leadership at every level of an organization. From team leaders to plant managers, these daily and weekly practices build discipline, drive accountability, and sustain performance improvements.

Read More »Automotive KPIs: The Complete Guide to Performance Metrics

Automotive companies thrive on precision. The right Key Performance Indicators (KPIs) transform raw data into actionable insights, helping leaders drive profitability, efficiency, and customer satisfaction. This guide explores the top 50 automotive KPIs, grouped by department, to help organizations measure what matters most.

Read More »