Black Belt Training

Team Project Charter

The Project Brief or Charter should include: A short description of the projectBackground information that may explain why the project is considered necessaryThe Objectives or Deliverables of the projectA clear definition of the scopeThis is done by using specific boundaries:i.e. what the Project includes,what the Project excludes,defining the project scope…

Read More »Defining Problem

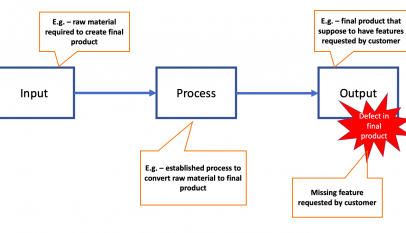

A problem is an undesirable situation which may be solvable by some agent although probably with some difficulty.

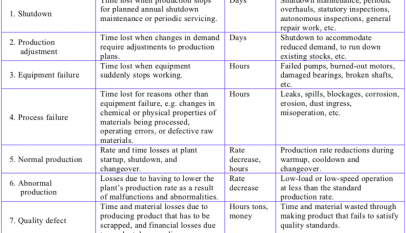

Read More »The 8 Big Plant Losses

In process industries, products are manufactured in equipment complexes (called “plant”) consisting of columns, storage tanks, heat exchangers, pumps, compressors, furnaces and other such units, all connected by pipes, instrumentation systems, and so forth. Because of this integration, it is more important to focus on maximizing the overall effectiveness of…

Read More »The 16 Big Losses and Related Costs

How does working patiently and persistently to eliminate the 16 Big Losses not only have the benefit of driving up OEEs, but also help greatly to drive down costs? If a plant has been working flat-out to meet demand, for example, with its operators doing overtime and holiday work, increasing…

Read More »