Lean Six Sigma

Lean Six Sigma Process Improvement Cycle – DMAIC

Master the DMAIC methodology (Define, Measure, Analyze, Improve, Control) at the core of the Lean Six Sigma process improvement approach.

Read More »Optimizing Changeover Times: A Lean Six Sigma Approach to Enhancing Food Packaging Line Efficiency

"Optimizing Changeover Times" is a Lean Six Sigma project focused on enhancing food packaging line efficiency by reducing changeover times between SKUs. Through the DMAIC framework, the project aims to minimize downtime, increase throughput, and deliver cost savings. Emphasizing data-driven decision-making and continuous improvement, this initiative seeks to set a…

Read More »Improving Process Flow with Spaghetti Diagrams

Spaghetti diagrams are a simple yet effective tool for improving process flow and reducing waste in any organization. By visualizing the flow of materials, people, and information through a process, organizations can identify areas of inefficiency and waste and make targeted improvements to optimize processes. This post explores the steps…

Read More »Seven Ways to Create a Continuous Improvement Culture

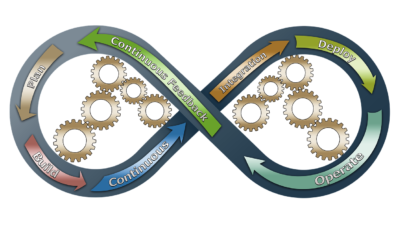

Creating a continuous improvement culture is crucial to any organization's success. In this article, we explore seven ways to build a continuous improvement culture in your workplace, including developing a shared vision, empowering employees, fostering collaboration, providing training and coaching, recognizing and rewarding improvement efforts, using data and metrics to…

Read More »