Lean

The Key to Cost Reduction and Customer Satisfaction: Understanding the 8 Wastes in Lean Office

To identify and eliminate the 8 Wastes in Lean Office, it is important to use a systematic approach, focusing on process improvement, training, or implementing new technologies or equipment. Continuous improvement is essential, with regular monitoring and evaluation of the process to ensure waste is being eliminated and efficiency is…

Read More »The Synergy of Lean Manufacturing and Artificial Intelligence: Optimizing Production Processes

Lean Manufacturing is a methodology that aims to optimize production processes by minimizing waste and maximizing efficiency. With the emergence of Artificial Intelligence (AI) technology, there is an opportunity to improve Lean Manufacturing tools and methods by integrating AI to optimize manufacturing processes further. AI can assist Lean Manufacturing by…

Read More »Lean Leadership: The Importance of Standard Work

Leader Standard Work (LSW) is more than a checklist—it’s a disciplined system that helps leaders balance control, improvement, and coaching. Learn how to design your own LSW routine to drive consistency, reduce chaos, and build a culture of continuous improvement.

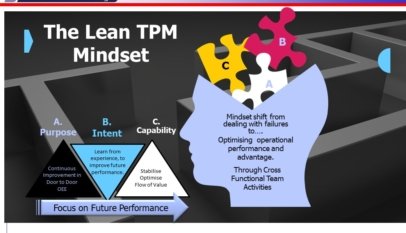

Read More »Lean and TPM as Equal Partners in Ratcheting Up Performance

When implemented together, Lean and TPM create a powerful partnership that serves to bolster operational excellence. The combination of these two tools provides manufacturers with a comprehensive approach to health, safety, and sustainability, ensuring that all areas of the production process are optimized.

Read More »