Lean

Main Elements Guide for the 8 Key Steps of EEM

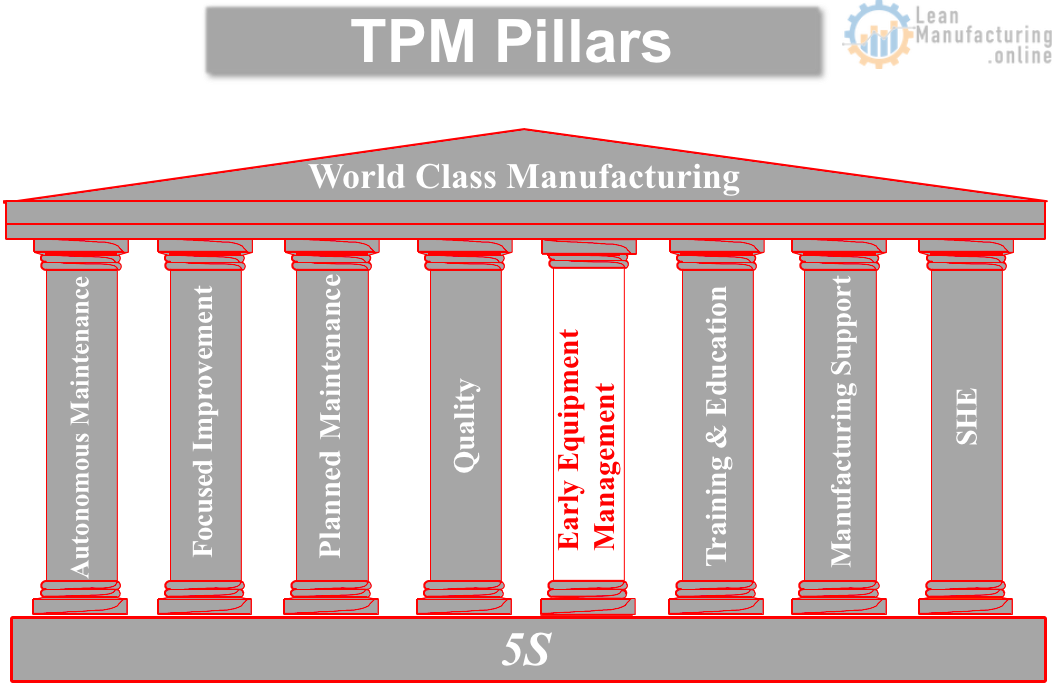

MAIN STEP ELEMENTS FOR YOUR PROJECT Step 1: EEM Project Definition Write and sign SCOPE Project kick-off with project TEAM Define KPI’s and Targets based on the project charter Ensure stakeholder expectations are clear. Conduct a DESIGN REVIEW with a checklist to include added parameters to the conceptual design. Required…

Read More »Loss Trees and Loss Deployment

What are Loss Trees? In general, Loss Trees are simply a listing of the losses (inefficiencies) which may exist in a factory production process. Loss Deployment is a cascade process that looks initially at the overall factory losses than increasingly at a more detailed level down to a packing line…

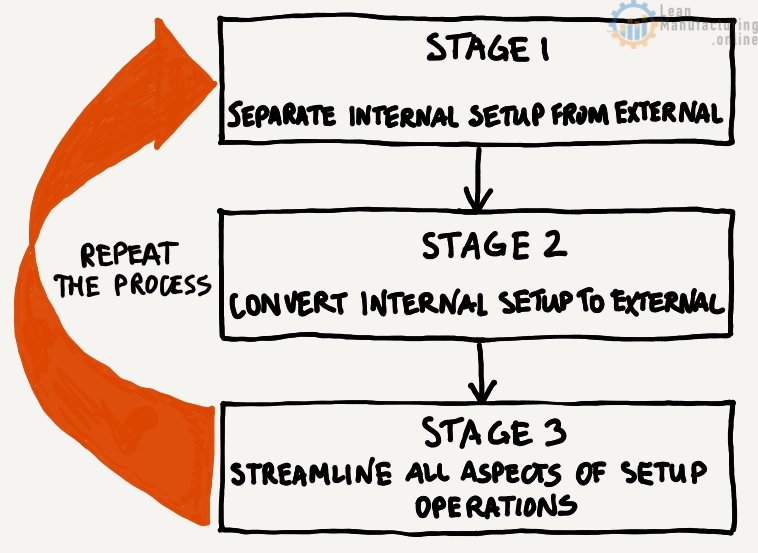

Read More »Single Minute Exchange of Die

SMED (Single Minute Exchange of Die) this is a set of techniques that make it possible to improve changeover performance and increase OEE. Objectives: Reduced downtime Increased flexibility Improved set-up time Goal: 75% reduction in set-up with relatively little capital Is not about: People reduction Set-up Time Definition Set-up Time:…

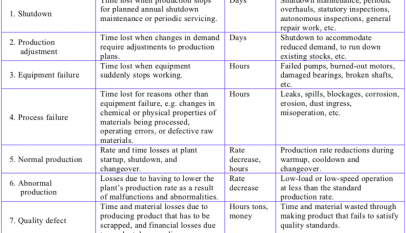

Read More »The 8 Big Plant Losses

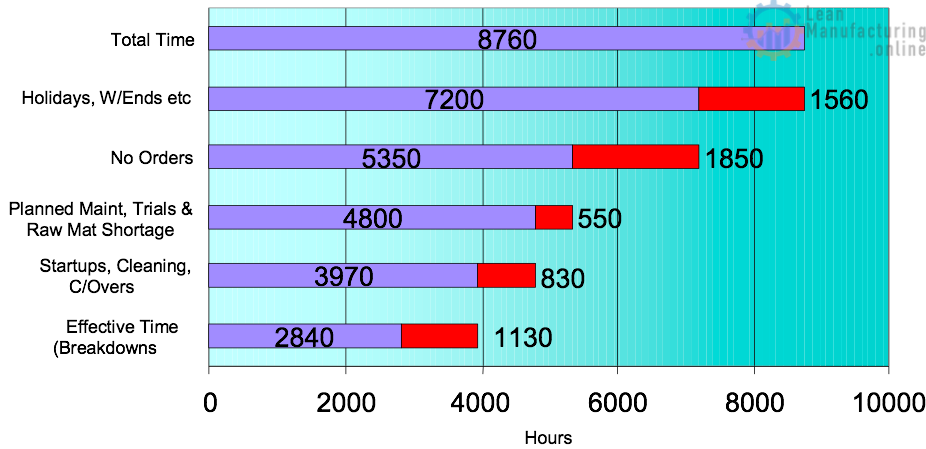

In process industries, products are manufactured in equipment complexes (called “plant”) consisting of columns, storage tanks, heat exchangers, pumps, compressors, furnaces and other such units, all connected by pipes, instrumentation systems, and so forth. Because of this integration, it is more important to focus on maximizing the overall effectiveness of…

Read More »