TPM

The History of Quality Maintenance and the Emergence of the Figure-of-Eight Method

Create flow diagram of individual processes for building in quality.

Read More »Determine Standard Values for Checks and Revise Standards

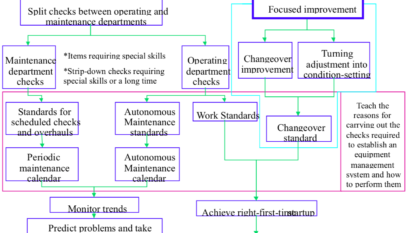

Standards for scheduled checks and overhauls.

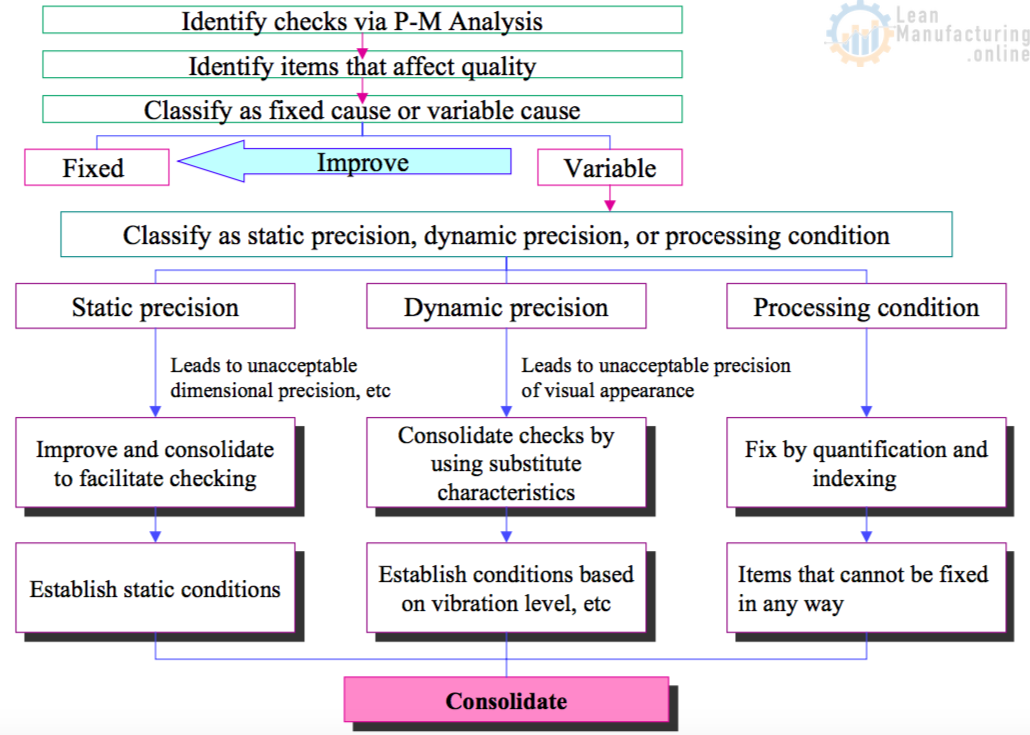

Read More »Developing Quality Maintenance. Consolidate Checking Methods

Each of the 4-M conditions established in Step 7 must be controlled to ensure 100% quality. However, they are usually very numerous, and the time required to check all of them can strain available resources. To make them manageable, they must be fixed (made so that they cannot change with…

Read More »Eliminate Flaws in 4-M Conditions and Finalize

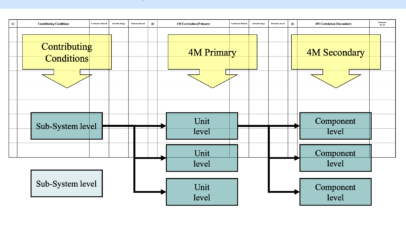

Review of 4M Conditions

Read More »