TPM

How to Improve Maintenance Efficiency with These Key Strategies

Improve your maintenance operations by focusing on equipment maintainability, tracking key metrics, and using balanced scorecards. Learn how these simple ideas can drastically enhance equipment reliability and boost collaboration between maintenance and production teams.

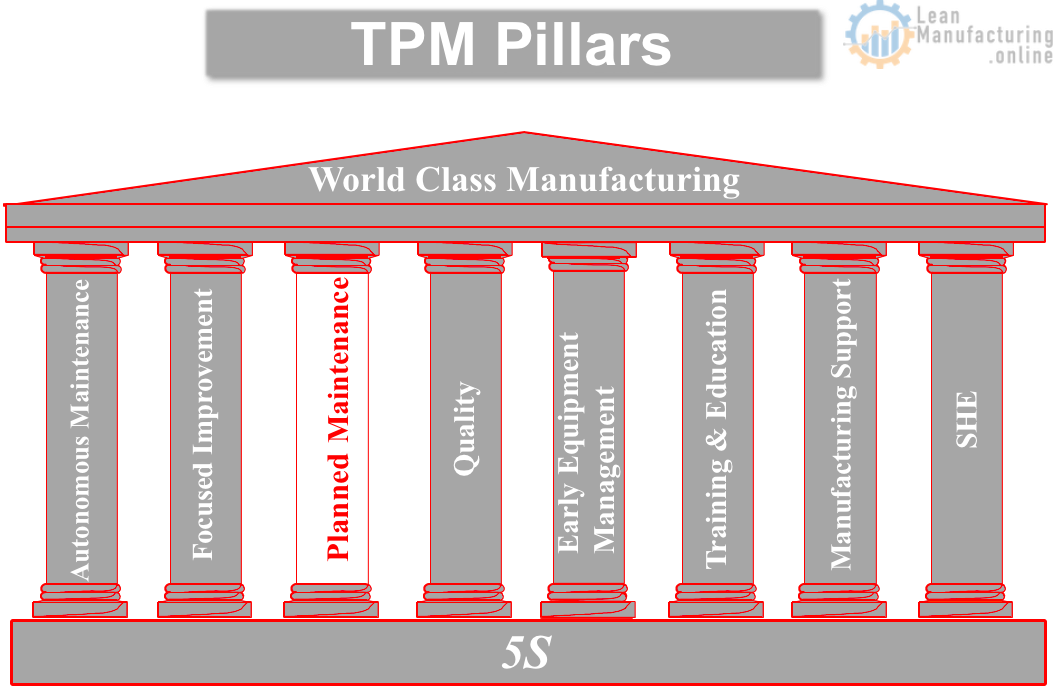

Read More »The Eight-Pillar Activities of Planned Maintenance in TPM

This blog post explores the eight-pillar activities of planned maintenance in Total Productive Maintenance (TPM), highlighting how organizations can transition from reactive to proactive maintenance strategies. By focusing on these key activities, companies can improve operational efficiency, reduce downtime, and ensure the alignment of maintenance and operations teams with strategic…

Read More »Mastering Gemba Walks: A Step-by-Step Guide for Continuous Improvement

Discover the transformative potential of Gemba Walks in your organization. This guide walks you through the essential steps to conduct effective Gemba Walks, enabling you to gain insights, foster collaboration, and drive meaningful improvements on the shop floor.

Read More »Unlocking Key Maintenance Metrics

Understanding maintenance metrics such as MTBF, MTTR, Failure Rate, and Reliability is crucial for optimizing maintenance operations and enhancing system reliability. This blog post delves into these essential metrics, providing insights on their definitions, usage, and impact on maintenance efficiency.

Read More »