TPM

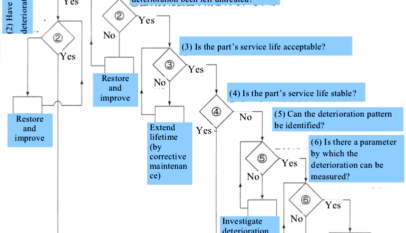

Prioritizing the Equipment and Selecting the Maintenance System

Each factory should determine its own machines’ priorities, depending on their effect on the factory’s overall production (volume and quality) and factors such as how much damage the machines would sustain if they broke down.

Read More »Zero-failure Programs

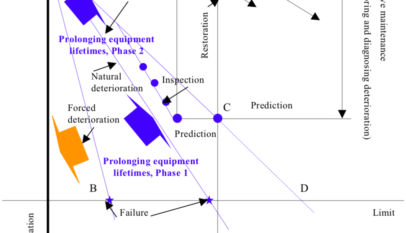

Effective maintenance is progressed by initiating activities designed to reduce failures and gradually building up a preventive maintenance system.

Read More »The Structure of Equipment Maintenance

Equipment maintenance can be defined as preventing machines from breaking down by selecting what type of maintenance should be used on which parts of which machines, formulating maintenance standards, and then systematically maintaining and controlling the machines in accordance with a maintenance calendar.

Read More »Management Issues

It is absolutely essential for management to clearly identify and fully understand the problems in the management system and the precise structure of the vicious circles it generates, before taking any action to reduce the number of equipment failures.

Read More »