Toyota Kata: How to Build a Culture of Daily Improvement That Sticks

When we think of Toyota, we often imagine smooth production lines, just-in-time delivery, or iconic lean tools. But beneath the surface lies something even more transformative: a deeply embedded culture of continuous improvement built through Kata.

Not the tools. Not just the techniques. But a pattern of behavior that’s practiced every single day.

Let’s break down what that really means—and how you can start using it to build a stronger, smarter, and more agile organization.

What Is Kata, Really?

Kata (型 or 形) is a Japanese term rooted in martial arts, meaning “form” or “pattern.” In martial arts, practicing a kata means repeating a set of movements until they become second nature.

Toyota applied this principle to business. And the result? A culture where people don’t just solve problems—they think scientifically and continuously improve how they solve problems.

Toyota Kata refers to two connected routines:

- Improvement Kata: A structured approach to achieving goals

- Coaching Kata: A method for teaching and reinforcing the Improvement Kata

In this post, we’ll zero in on the Improvement Kata, and show you how to bring it to life.

The 4-Step Routine: Improvement Kata

The Improvement Kata helps teams navigate uncertainty, solve real problems, and move toward meaningful goals—systematically.

Here’s how it works:

Step 1: Get the Direction or Challenge

Improvement starts with clarity. Where are you headed? Why does it matter?

Your focus here:

- Clarify long-term vision

- Align improvement efforts with strategy

- Choose a direction that excites and engages your team

Example: A company sets a long-term goal to reduce product delivery time by 60%. That becomes the guiding challenge for their teams.

Step 2: Grasp the Current Condition

You can’t improve what you don’t fully understand.

Your focus here:

- Observe the process firsthand (go to the Gemba)

- Document current performance with facts and data

- Identify current obstacles, friction points, or inefficiencies

Pro tip: Avoid assumptions. Let the process speak for itself.

Step 3: Establish the Next Target Condition

This is your short-term goal—what’s realistic and measurable in the next few weeks or months?

Your focus here:

- Set a target condition that moves you closer to the challenge

- Keep it specific and time-bound (1–3 months max)

- Define success metrics and expected outcomes

Example: Reduce machine changeover time by 20% within 6 weeks.

Step 4: Conduct Experiments to Get There

Now it’s time to apply Plan-Do-Check-Act (PDCA) cycles to close the gap.

Your focus here:

- Run rapid experiments daily or weekly

- Tackle one obstacle at a time

- Reflect, adapt, and try again

Remember: Improvement isn’t about having the “perfect” plan. It’s about learning faster than the problem evolves.

From Practice to Culture: Embedding the Improvement Kata

When you make these four steps a daily rhythm, something powerful happens. Scientific thinking becomes a habit. Improvement becomes a way of life—not a special event.

Here’s how to bring it into your organization:

Start Small

Choose one pilot process. Use the Kata sheet to track everything:

- Current condition

- Target condition

- Obstacles

- Experiments

- Learnings

Assign one coach to guide the routine. Keep it focused and visible.

Use the Kata Sheet Properly

Your Kata sheet is your improvement GPS.

- Document dates for each target condition

- Clearly define process metrics

- Keep an “obstacle parking lot” to focus your PDCA cycles

- Capture pre-experiment expectations and post-experiment results

This makes learning transparent and transferable across teams.

Avoid These Common Pitfalls

- Setting goals that are vague or too broad

- Skipping direct observation of current processes

- Running experiments without defined expectations

- Not having a regular coaching rhythm

Build discipline into the routine. That’s what drives culture change.

Case Study: Kata in Action

Let’s look at how one mid-sized medical device manufacturer put the Improvement Kata to work:

Challenge: Cut lead time by 50%

Step 1: They defined this as their long-term vision

Step 2: Observed current conditions on the production floor

Step 3: Set an initial target: reduce setup time by 25% in 6 weeks

Step 4: Conducted daily PDCA cycles with frontline coaching

Results:

- Target hit in just 4 weeks

- Daily improvement routines established

- Cross-team capability to adapt became a competitive advantage

Make Improvement a Way of Thinking

The real magic of Toyota Kata isn’t the framework—it’s the mindset it builds.

When your teams practice structured experimentation daily, they learn to thrive in uncertainty. Problems become learning opportunities. And your organization becomes more adaptable, resilient, and aligned—one PDCA cycle at a time.

Next Step: Try It Yourself

Pick one process. Define your challenge. Use the Improvement Kata routine to make progress every day. Start small, stay consistent, and watch your team evolve.

Let improvement become your default setting.

Self-Coaching Structure for Toyota Kata

1. Start with Clarity: Define Your Challenge

Before anything else, ground yourself in the bigger picture.

Ask Yourself:

- What’s the challenge I’m aiming to meet?

- Why does this matter to my team, my organization, or my customer?

- How does this align with our long-term goals?

Tip: Write your challenge on a sticky note and keep it visible. It becomes your north star.

2. Observe and Reflect: Grasp the Current Condition

Before planning any improvements, understand where things really stand.

Daily Prompts:

- What does the process look like right now?

- What results am I currently getting?

- What obstacles or inefficiencies am I noticing?

- What evidence or data supports this?

Tool: Use a simple observation log. Note the facts, not opinions. Keep it visual if possible (draw it out).

3. Set the Next Target Condition

Now that you know where you are, decide where you want to be next.

Define:

- A measurable outcome you can reach in the next 1–4 weeks

- Key process characteristics you expect to see

- A date to achieve it by

Reflection Check:

- Is it challenging, but achievable?

- Can I track progress daily or weekly?

4. Run Daily or Weekly PDCA Experiments

This is where you move forward in small, focused steps. Each experiment helps you test your assumptions and close the gap.

Experiment Cycle (PDCA):

- Plan: What will I try today or this week? What do I expect will happen?

- Do: Execute the plan.

- Check: What actually happened?

- Act: What did I learn? What’s the next step?

Self-Coaching Tip:

Ask these after each cycle:

- Did the result match my expectation?

- What did I learn about the process?

- What should I change next time?

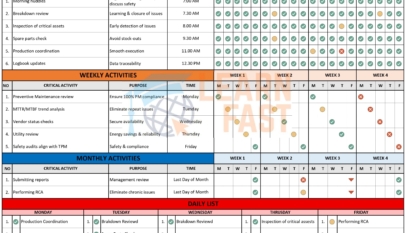

5. Track Your Progress Visually

A simple dashboard or visual tracker helps reinforce your learning and keeps your momentum high.

What to include:

- Challenge statement

- Current condition summary

- Target condition and due date

- List of completed PDCA experiments

- Key learnings from each experiment

Optional: Create a wall or digital board with sticky notes or Kanban cards to visualize progress.

6. Self-Reflection Routine (Weekly or Biweekly)

Build in regular pauses to reflect and reset your direction.

Ask Yourself:

- Am I still moving toward my challenge?

- Are the obstacles I’m seeing different than I expected?

- What patterns are emerging in the way I solve problems?

- Where could I be more specific or disciplined?

Bonus Reflection:

Write a short learning summary every two weeks. Keep it to three points:

- Biggest insight

- Hardest moment

- What I’ll do differently next

7. Common Traps to Watch For

Be your own best coach by watching for signs you’re drifting off-course:

- Are my target conditions vague? (Make them measurable.)

- Am I skipping observation and jumping to solutions? (Pause. Go to the facts.)

- Are my experiments too big? (Smaller = faster learning.)

- Am I ignoring obstacles and just “trying harder”? (Work on the process, not the person.)

8. Celebrate Small Wins

Improvement isn’t just about outcomes—it’s about building capability.

Reward Yourself:

- When you hit a target condition, pause to celebrate

- Capture how your thinking evolved

- Share the journey with your team or peers

This builds your momentum—and spreads the mindset.

Summary: Your Self-Coaching Routine

| Routine Step | Self-Coaching Prompt |

|---|---|

| Define Challenge | “What’s the meaningful problem I’m trying to solve?” |

| Observe Current State | “What’s really happening, and what evidence do I have?” |

| Set Target Condition | “What measurable change do I want to see soon?” |

| Run Experiments (PDCA) | “What will I try, what do I expect, and what happened?” |

| Reflect Weekly | “What am I learning? What should I adjust?” |

| Watch for Pitfalls | “Am I being specific, disciplined, and focused?” |

| Celebrate Progress | “What did I accomplish, and how did I grow?” |