A Look Back at Traditional Performance Reviews

For decades, the annual performance review has been a cornerstone of corporate culture. Traditionally, this process involved a once-a-year meeting between an employee and their manager to discuss performance, set goals, and possibly discuss a salary increase or promotion. This method, rooted in the industrial age’s hierarchical and regimented work environments, aimed to ensure employees were meeting their job requirements. However, this system, while straightforward, has increasingly shown its limitations.

The Challenges of Annual Reviews

Annual reviews often create stress for both employees and managers, turning what could be an opportunity for constructive dialogue into a dreaded administrative task. Critics argue that this system is too rigid to accommodate modern businesses’ fast-paced and flexible work environments. It can also lead to a lack of timely feedback, leaving employees wondering how they can improve throughout the year. Furthermore, these reviews can be biased, as they rely heavily on the manager’s perspective and memory, potentially overlooking key achievements or challenges the employee faces over the year.

The Shift Towards Continuous Feedback

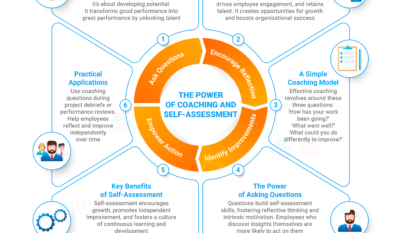

Recognizing these limitations, many organizations are moving away from the traditional annual review process in favour of a more dynamic approach: continuous, real-time feedback. As noted by The Wall Street Journal, this method emphasizes the importance of ongoing communication between managers and their teams. It allows for immediate recognition of achievements and swift correction of mistakes, fostering a culture of growth and adaptability.

Innovative companies, such as the software startup Fountain, are experimenting with creative feedback methods, including using sticky notes during meetings to provide instant assessments of helpfulness. Moreover, the integration of artificial intelligence through chatbots for rehearsing difficult conversations marks a significant leap forward in performance management technology.

The Power of Inclusion and Reciprocity

The modern approach to performance evaluations recognizes the value of bidirectional feedback. It’s not just about managers reviewing employees but also about employees having a voice to share their perspectives on leadership and the organization. Implementing 30/60/90 day reviews with new hires, as practiced in some companies, embodies this principle by offering a structured format for newcomers to express their early experiences and concerns, thereby fostering a culture of mutual growth and understanding.

Conclusion: Embracing the New Paradigm

The transition from annual performance reviews to continuous feedback mechanisms reflects a broader shift in workplace dynamics. It moves away from a top-down, hierarchical approach to a more collaborative, flexible, and responsive model. This evolution aligns with the changing nature of work in the 21st century, where adaptability, instant communication, and mutual respect are paramount.

As organizations continue to explore and refine these new methods, the ultimate goal remains clear: to create a work environment that not only drives productivity and innovation but also supports the personal growth and satisfaction of every employee. In doing so, businesses are not just improving their performance review processes; they are redefining the very essence of their organizational culture for the better.