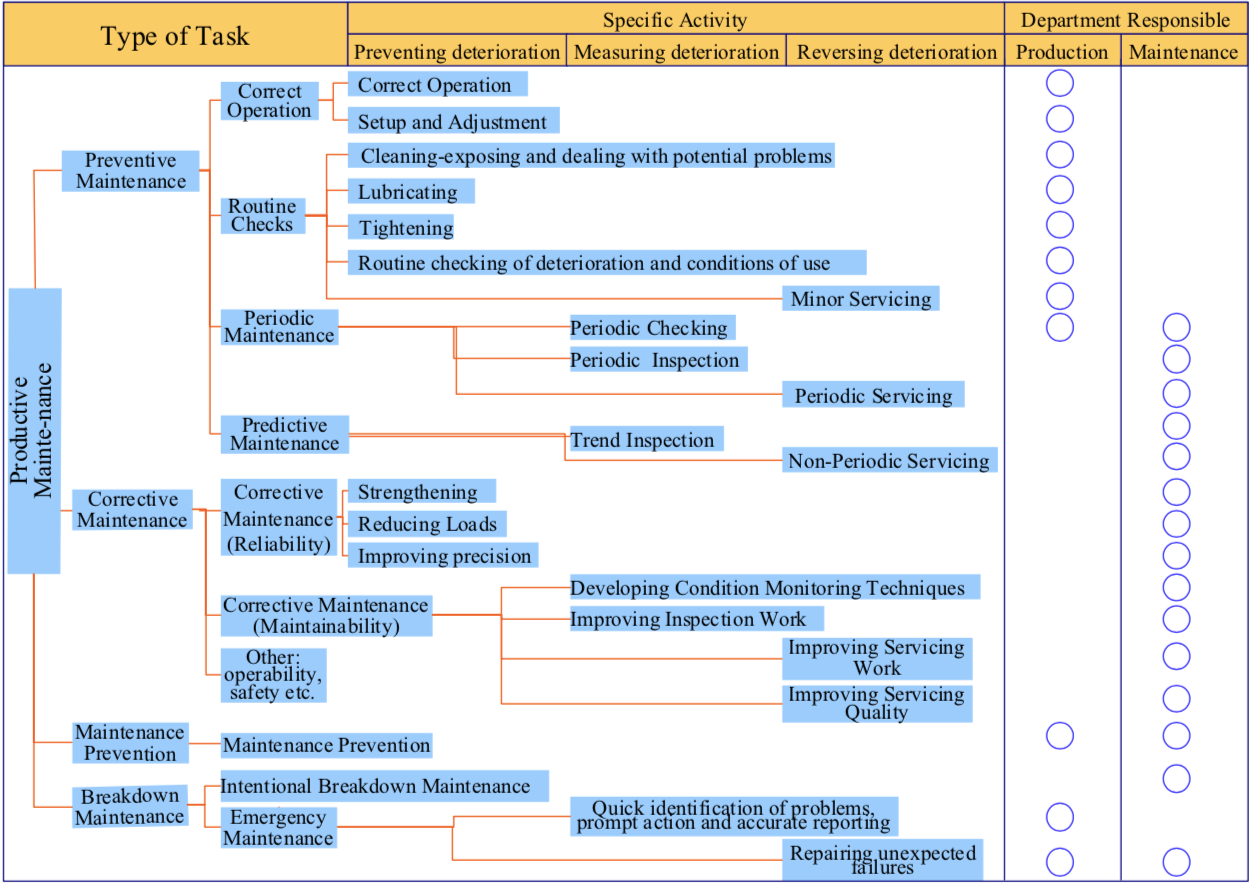

The production and maintenance departments have their own respective roles to play in sustaining and improving OEE (Overall Equipment Effectiveness) by maintaining equipment reliably and economically (see Figure “How the Responsibility for Maintenance Should be Allocated (Example)”).

First, the equipment’s operators must:

- Carefully sustain basic equipment conditions (by periodically cleaning, lubricating and re-tightening).

- Maintain the correct operating conditions (mainly by performing external checks and following correct operating practices).

- Identify the areas that tend to deteriorate most rapidly (chiefly by visual inspection when restoring the equipment), and use their five senses to spot early warning signs of trouble.

- Continually improve their inspection skills as well as their operating skills (for working the equipment, performing changeovers, etc.).

These are the four principal activities the operators should engage in, under the umbrella of Autonomous Maintenance.

Meanwhile, the maintenance department must:

- Provide technical assistance to support the production department’s Autonomous Maintenance program.

- Scrupulously eliminate deterioration through regular checking, inspection, and strip-down overhaul.

- Identify design weaknesses, specify precise operating conditions, and improve the equipment effectively and reliably.

- Improve their skills for checking, inspection, strip down overhaul, and other maintenance tasks.

It is essential for the production and maintenance departments to work closely together if the maintenance program is to go ahead smoothly. This means that the production department must take responsibility for some of the maintenance functions in addition to its operating duties, while the maintenance department must assume responsibility for production in order to ensure that productive maintenance takes place.

The roles of the operating and maintenance departments

(1) The operating department

The day-to-day management of the equipment is what determines its productivity, quality, and safety, and the operating department must undertake this as one of its essential duties (managing the equipment on a daily basis must be treated as part of the operating department’s responsibility; it should not be thought of as the operating department doing some of the maintenance department’s work for them).

For this to happen, operators must learn how to check, clean, and lubricate their equipment and perform other essential routine management tasks, while developing their ability to recognize abnormalities.

(2) The maintenance department

As the maintenance specialists, the maintenance department should perform tasks such as repairing equipment when it breaks down, periodically overhauling it to reverse deterioration, monitoring its performance, and performing corrective maintenance to increase its reliability and maintainability. To accomplish this, it must cultivate higher and higher levels of the necessary maintenance expertise and skills.

The maintenance department must also provide the necessary training to support the operating department in acquiring the maintenance knowledge and skills it needs to manage its equipment from day to day.

The real job of the maintenance department, however, is to sustain and progressively raise its level of technical expertise while increasing the efficiency of the maintenance work. The maintenance department should focus its energies on these tasks in a conventional way.

Scope of Autonomous Maintenance performed by the operating department

1 Routine management tasks for keeping the equipment working properly

- Cleaning, checking, lubricating, retightening, replacing consumable parts, etc.

- Detecting and correcting abnormalities, and improving the equipment, through the medium of these tasks

- Taking action to reduce the level of minor stops

- Creating and continually updating standards associated with the above work

2 Work-related to operating conditions and quality conditions

- Robot teaching, controlling welding conditions, grinding and replacing welding tips

- Maintaining and controlling the precision of gauges, clamps, etc.

- Keeping painting lines clean (this leads directly to better quality)

- Controlling the conditions under which guns and nozzles used for paint spraying, adhesive application, and so on are operated

- Controlling die-molding conditions