Essential Skills Every Mechanical Engineer Must Master

The role of a mechanical engineer has evolved far beyond traditional design and manufacturing tasks. Modern engineers are expected to combine technical knowledge with advanced problem-solving, quality control, and digital integration. Companies worldwide seek professionals who can design innovative products, ensure flawless quality, and adapt to Industry 4.0 technologies.

To succeed in this environment, engineers must build expertise in five key areas:

- Design Engineering

- Quality Engineering

- Manufacturing Engineering

- Industry 4.0 Automation & Robotics

- Metrology & QA

Design Engineering – The Foundation

Every great product starts with a robust design. Mechanical engineers must master the art of visual communication through precise drawings and advanced tools.

- Engineering Drawing: The language of engineering. It defines specifications, tolerances, and ensures accurate communication across teams.

- GD&T (Geometric Dimensioning & Tolerancing): Precision matters. GD&T ensures that components fit together perfectly, reducing assembly errors and failures.

- AutoCAD: A must-have software for creating detailed 2D and 3D designs quickly and accurately.

- SolidWorks 2024: Going beyond drawings, SolidWorks allows advanced 3D modeling, simulations, and design optimization.

Strong design skills not only enhance product development but also reduce costly rework during manufacturing.

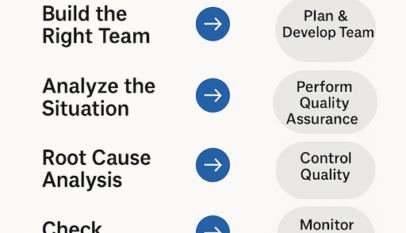

Quality & Manufacturing Excellence

In a world where customers demand zero defects, quality engineering skills make you an indispensable asset.

- QC Tools: Tools like Pareto charts, cause-and-effect diagrams, and control charts help identify problems and implement corrective actions.

- Kaizen: Continuous improvement philosophy that engages everyone in the organization to eliminate waste and improve processes.

- Six Sigma: A structured methodology for defect reduction and process improvement.

- Lean Tools: Techniques such as 5S, value stream mapping, and SMED enhance productivity and eliminate waste.

- Total Quality Management (TQM): A company-wide approach to embedding quality in every process.

On the manufacturing side, engineers need practical exposure to:

- CNC Programming: Precision in machining.

- EV Technologies: Power the future of transportation.

- IC Engine Basics: Core mechanical knowledge.

- Material Handling Techniques: Efficient workflow and safety.

Industry 4.0, Automation & Metrology

The future belongs to engineers who embrace digital technologies.

- Mechatronics: The fusion of mechanical engineering with electronics and robotics. Essential for smart automation systems.

- PLC Programming: Learn to program and control automation systems for efficient operations.

- Digital Manufacturing: Integration of digital technologies into traditional manufacturing for real-time monitoring and predictive maintenance.

- 3D Printing: Revolutionizing prototyping and production with additive manufacturing.

Finally, Metrology & QA are vital to ensure accuracy:

- Engineering Metrology

- 3D Measurement Systems

- CMM Machines

- Calibration Processes

- Uncertainty Measurement

- Basic QMS (Quality Management System)

Mechanical engineering is no longer just about machines—it’s about innovation, quality, and smart technology integration. By mastering these essential skills, you position yourself as a future-ready engineer prepared for any challenge.