The DMAIC (Define, Measure, Analyze, Improve, Control) methodology is the cornerstone of Lean Six Sigma, providing a structured approach to process improvement. Each phase builds upon the previous, creating a cohesive system for solving problems and optimizing performance. Let’s explore each phase in depth.

Define: Setting the Foundation for Success

Every improvement begins with clarity. The Define Phase focuses on establishing a clear understanding of the problem, its impact, and the objectives. Key elements include:

- Project Charter: Outlining the problem, scope, goals, and team roles.

- Voice of the Customer (VOC): Identifying customer needs and expectations.

- High-Level Process Maps: Visualizing workflows to pinpoint inefficiencies.

This phase ensures alignment and sets the stage for success.

Link to Define Phase: https://zbk.li/Define

Measure: Gathering Data for Insight

The Measure Phase is about capturing data to understand the current process performance. This phase includes:

- Critical-to-Quality (CTQ) Factors: Identifying what matters most to customers.

- Data Collection and Validation: Ensuring data accuracy through measurement system analysis.

- Process Mapping and Capability Analysis: Highlighting areas of inefficiency or variability.

By focusing on reliable data, this phase eliminates guesswork and lays a factual foundation.

Link to Measure Phase: https://zbk.li/Measure

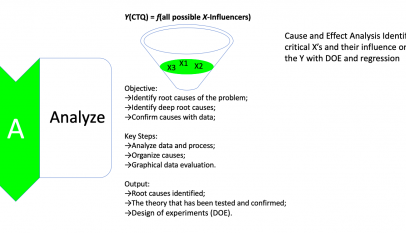

Analyze: Uncovering the Root Cause

Data without analysis is just noise. The Analyze Phase dives into the “why” behind inefficiencies, using tools like:

- Root Cause Analysis: Techniques such as Fishbone Diagrams and 5 Whys.

- Hypothesis Testing: Validating assumptions with statistical rigor.

- Multi-Vari Analysis: Pinpointing variations and their impact.

This phase ensures solutions target the core issues, not just symptoms.

Link to Analyze Phase: https://zbk.li/Analyze

Improve: Implementing Effective Solutions

The Improve Phase is where change happens. Using insights from analysis, teams develop and test solutions that drive measurable improvement. Highlights include:

- Design of Experiments (DOE): Testing variables to find optimal settings.

- Prototyping and Validation: Ensuring solutions are effective in real-world scenarios.

- Implementation Plans: Rolling out improvements across the process.

This phase transforms ideas into actionable, sustainable changes.

Link to Improve Phase: https://zbk.li/Improve

Control: Sustaining the Gains

Success is not just achieving improvements—it’s maintaining them. The Control Phase focuses on embedding changes into everyday operations, with methods like:

- Control Charts and Statistical Process Control (SPC): Monitoring ongoing performance.

- Standard Operating Procedures (SOPs): Documenting best practices.

- Mistake-Proofing (Poka-Yoke): Preventing errors through simple yet effective solutions.

By establishing robust controls, this phase ensures improvements endure.

Link to Control Phase: https://zbk.li/Control

The DMAIC methodology is more than just a toolset—it’s a mindset. By progressing through Define, Measure, Analyze, Improve, and Control, organizations can tackle challenges methodically and achieve sustainable improvements. The key to DMAIC’s power lies in its structure, ensuring that every phase builds toward actionable insights and measurable outcomes. Whether you’re new to Lean Six Sigma or an experienced practitioner, mastering DMAIC is essential for driving meaningful change. Start your journey today, and watch your processes transform into benchmarks of efficiency and excellence.