Blog

Avoiding OKR Mistakes and Misapplications

Navigating the OKR journey can sometimes be challenging. In the quest to effectively leverage Objectives and Key Results (OKRs), organizations can often encounter pitfalls and missteps. Our guide, "Avoiding OKR Mistakes and Misapplications," provides insights into common errors in OKR implementation and application. It offers practical strategies to sidestep these…

Read More »Understanding the Core Essentials of a Project: A Comprehensive Overview

This article delves into the core concept of what constitutes a project. It explains how a project is a temporary endeavor with a unique goal and a defined budget. By differentiating between project work and operations, the article offers insights into the unique nature of project outcomes. It also elaborates…

Read More »Mastering the Art of Technical Report Writing

Mastering technical report writing is essential across various professions. This skill involves presenting complex data clearly and concisely, enabling effective communication and decision-making. Key steps include understanding the report's purpose and audience, conducting thorough research, creating a logical structure, employing clear and precise language, using visuals effectively, and refining through…

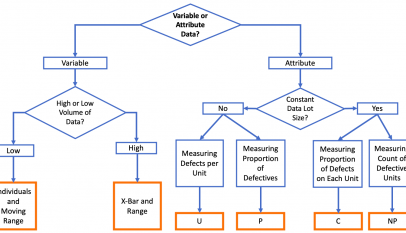

Read More »Understanding Average, Variation, Capability and Their Applications in Process Improvement

Explore key statistical concepts such as average, variation, and capability, and learn their applications in process improvement. Understand how to calculate and interpret Cp and Cpk, and use these metrics to enhance process performance. Discover how to convert Cp and Cpk to the percent of failure, helping organizations prioritize improvement…

Read More »