Blog

Preventive maintenance plan (PM program). Fundamental Phase Action Plan

There are seven very distinct elements or clusters to put in place in the Fundamental Phase. The elements are in a natural “make sense” order; some can be completed simultaneously with available resources. The last one, “Basic Maintenance Management,” can and should be inserted at the right time to aid…

Read More »Embrace Positive Change with the SOAR Analysis Model

Discover the power of the SOAR Analysis model, a strengths-based approach to change management that fosters collaboration, learning, and innovation. This versatile tool can be applied to strategic planning, personal development, and more. By focusing on strengths, opportunities, aspirations, and results, the SOAR model helps organizations and individuals embrace positive…

Read More »Boost Your Preventive Maintenance Performance with a Targeted Gap Analysis

Unleash the full potential of your preventive maintenance program by conducting a targeted gap analysis. This powerful tool evaluates your current maintenance approach, identifies areas of inefficiency, and helps prioritize improvements for maximum effectiveness. Discover the key steps to implementing a successful gap analysis, from defining the scope to developing…

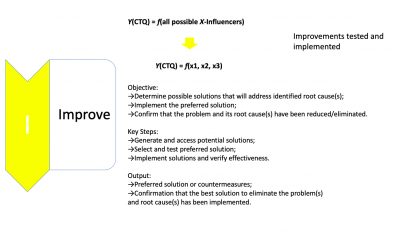

Read More »Mastering the Improve Phase in DMAIC: Black Belt-Level Strategies and Techniques

Unleash the full potential of the Improve phase in DMAIC with this comprehensive guide, specifically tailored for Lean Six Sigma Black Belts. Delve into advanced tools and methodologies, from brainstorming techniques like SCAMPER to Design of Experiments, and explore change management strategies and sustaining improvements. Master the art of driving…

Read More »