Blog

Building a Resilient Workforce: 7 Keys to Successful Strategy Execution

Boost your team's resilience and enhance strategy execution with these seven powerful techniques. Develop a positive mindset, emotional intelligence, and problem-solving skills, while emphasizing self-care and open communication. By investing in resilience training and fostering a supportive work environment, you can unlock your organization's full potential and achieve long-term success.

Read More »The Role of BPM in Achieving Agility and Competitive Advantage

In a rapidly changing global economy, organizations need to adopt agile business models to stay competitive. Business Process Management (BPM) offers a systematic approach to managing, optimizing, and streamlining processes, enabling businesses to increase productivity, expedite time-to-market, expand their global reach, achieve compliance, and accelerate innovation. By embracing BPM, organizations…

Read More »12 Wastes to Eliminate in Product and Process Development

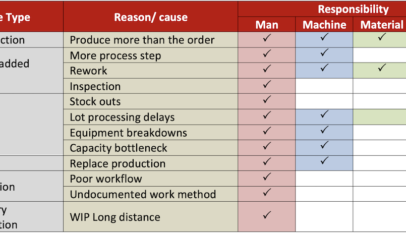

Discover how to boost efficiency in manufacturing by identifying and eliminating 12 common wastes in product and process development. This comprehensive guide covers strategies for reducing overproduction, waiting time, transportation waste, and more, paving the way for increased competitiveness and long-term success in the manufacturing sector.

Read More »Mastering Your Email Communication: How to Email Like a Boss

Discover how to master email communication and make a lasting impression with these essential tips. From crafting engaging subject lines to maintaining a professional tone, learn the strategies to help you email like a boss and boost your workplace productivity.

Read More »