Blog

Mastering Your Marketing Plan: A Guide to the SOSTAC® Planning System

SOSTAC® is a comprehensive planning framework that helps businesses develop effective marketing plans. It provides a structured approach to creating and implementing a marketing plan, with a focus on achieving business goals. The SOSTAC® system is comprised of six components: Situation analysis, Objectives, Strategy, Tactics, Action, and Control. Each of…

Read More »Enable, Empower, and Encourage

Discover how to cultivate an environment that nurtures innovation, collaboration, and continuous improvement, ultimately driving exceptional performance and success.

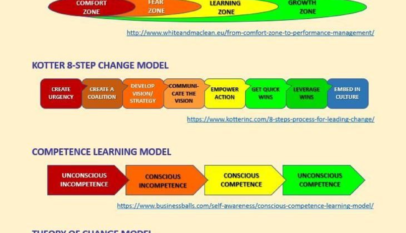

Read More »Overcoming Change Resistance and Facilitating Effective Response

Overcoming change resistance in organizations is essential for growth and improvement. By understanding the reasons behind resistance, such as fear of the unknown and lack of trust, leaders can implement effective responses like clear communication, employee involvement, and providing support, ultimately facilitating successful change.

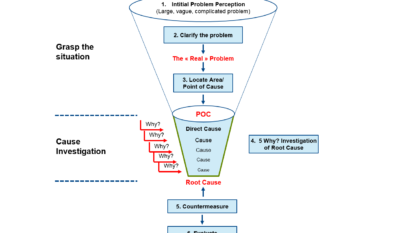

Read More »Embracing The Toyota Way: A Practical Problem-Solving Framework for Improved Efficiency

This framework was inspired by The Toyota Way, a management philosophy emphasizing continuous improvement and respect for people. The framework consists of five distinct stages: defining the problem, breaking down the problem, setting targets, analyzing root causes, and implementing countermeasures. By following this systematic approach, organizations can effectively address challenges,…

Read More »