Problem-Solving

How do you ensure that your quarterly Objectives are both ambitious and achievable?

Balancing ambitious and achievable quarterly objectives involves aligning them with strategic goals and ensuring they're SMART (Specific, Measurable, Achievable, Relevant, Time-bound). Using historical data and industry benchmarks can help set realistic targets. Employee involvement in setting these objectives can foster a sense of ownership and motivation. Regular review and adjustments…

Read More »Unveiling the ETERNAL Method: A Comprehensive Approach to Problem-Solving and Knowledge Acquisition

Discover the ETERNAL (Examine, Theorise, Experiment, Review, Normalise, Apply, Learn) method, a powerful approach for effectively addressing challenges, acquiring new skills, and developing expertise. This comprehensive framework integrates critical thinking, scientific inquiry, and applied learning to help individuals and organizations excel in personal and professional development, fostering a growth mindset…

Read More »Unlocking the Secrets of Problem-Solving: The 8-Step Path to Success

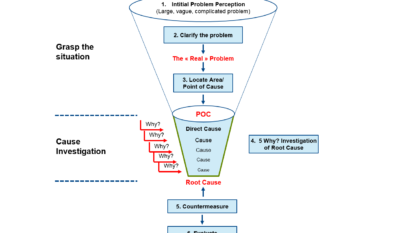

Discover the 8-step problem-solving process that can help you tackle challenges more effectively. This comprehensive framework covers problem clarification, root cause analysis, developing countermeasures, implementation, monitoring results, and standardization, leading to continuous improvement and lasting success.

Read More »Embracing The Toyota Way: A Practical Problem-Solving Framework for Improved Efficiency

This framework was inspired by The Toyota Way, a management philosophy emphasizing continuous improvement and respect for people. The framework consists of five distinct stages: defining the problem, breaking down the problem, setting targets, analyzing root causes, and implementing countermeasures. By following this systematic approach, organizations can effectively address challenges,…

Read More »