Blog

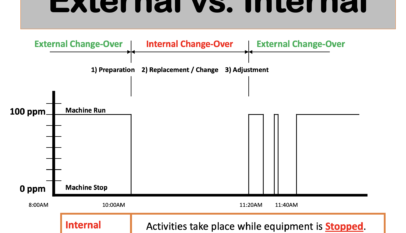

External activity vs. Internal activity – Knowing this can make a world of difference in the efficiency of your changeovers

Changeovers are required to ensure that we can satisfy the different needs of a customer. Reducing the time to do a changeover holds the key to how quickly we can respond to a customer’s needs. Also, quick changeover means less downtime, which translates to more efficiency, productivity, and parts! How…

Read More »Maximizing Employee Engagement: The Power of the Gallup 12 Hierarchy

The Gallup 12 Engagement Hierarchy provides a comprehensive framework for organizations to increase employee engagement and improve business outcomes. From trust in leadership to involvement in team building, this hierarchy covers all the key elements that drive employee engagement. By focusing on these 12 elements, organizations can create a positive…

Read More »LinkedIn Learning: An In-Depth Guide to Its Cost and Features

Blog Courses Education Lean Six Sigma Process Excellence Project Management Supply Chain TPM TPS World Class Manufacturing

LinkedIn Learning is an online learning platform that offers a variety of courses and tutorials on topics such as business, technology, creative arts, and more. With its flexible pricing options, including a free trial, and expert instructors, the platform provides users with a valuable learning experience. Whether you're looking to…

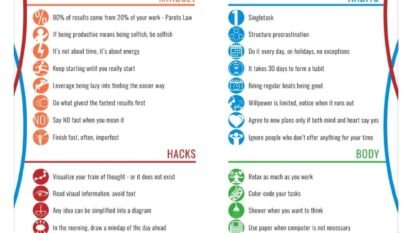

Read More »How Productivity Works: An In-Depth Guide

Productivity is a crucial aspect of business success, and it refers to the amount of output produced per unit of input. In this post, we'll explore the concept of productivity and how it works in detail. From understanding the productivity formula to the key factors that affect it, and the…

Read More »