Blog

Teams, Titles & Tepees (RASCI and beyond)

RASCI is just one of many tools that can be used to help manage projects and teams. There are other models and frameworks that have been developed to address the needs of more complex and dynamic organizations.

Read More »SWOT Analysis

SWOT analysis is a popular strategic planning tool that helps organizations understand their strengths, weaknesses, opportunities, and threats. By identifying these key factors, organizations can make informed decisions about their future direction and identify areas for improvement.

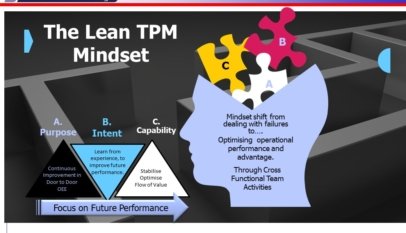

Read More »Lean and TPM as Equal Partners in Ratcheting Up Performance

When implemented together, Lean and TPM create a powerful partnership that serves to bolster operational excellence. The combination of these two tools provides manufacturers with a comprehensive approach to health, safety, and sustainability, ensuring that all areas of the production process are optimized.

Read More »Quality Planning

Quality Planning is the process of defining the quality policies, objectives, and responsibilities so that the project stakeholders can understand the quality expectations and requirements. It involves identifying the quality standards that are relevant to the project, determining the necessary resources for quality control, and developing a plan for quality…

Read More »