Blog

Standard Operating Procedure vs. Work Instructions

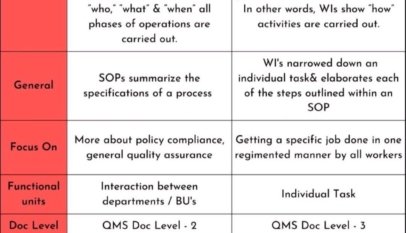

SOP A standard operating procedure (SOP) is a set of step-by-step instructions that provides clear and consistent guidance on performing a particular task or activity. SOPs are designed to help ensure that work is performed consistently and in compliance with relevant regulations and guidelines. They can be used in various…

Read More »Hoshin Kanri

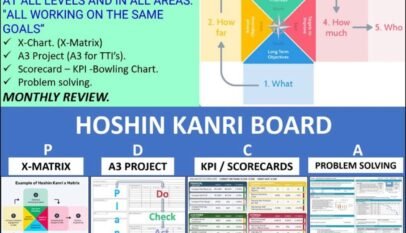

Hoshin Kanri, also known as policy deployment, is a management approach to align an organization’s goals and strategy with its daily operations. It involves setting clear, measurable objectives and creating a plan to achieve them through the coordinated efforts of all levels of the organization. It typically involves several key…

Read More »What is the SDLC method?

The SDLC, or Software Development Life Cycle, is a process for planning, developing, testing, and deploying software applications. It is a systematic approach that helps to ensure that the software is of high quality, meets the needs of the users, and is delivered on time and within budget. The SDLC…

Read More »Project Management

Define the project To define a project, you will need to identify the goals and objectives of the project, as well as the stakeholders who will be involved. This can be done through a stakeholder analysis process, where you identify and assess each stakeholder’s interests, needs, and potential impacts on…

Read More »