Millwright

Millwrights and Mechanics Guide. Drawing and Sketching. Part 1

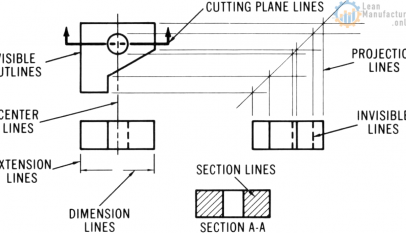

Drawings and sketches are universally used to communicate technical information. They are the graphic…

Drawings and sketches are universally used to communicate technical information. They are the graphic…

The purpose of this procedure is to define the steps to do a 4M …