Black Belt Training

Brainstorming

A group technique for generating new useful ideas. It uses a few simple rules for discussion that increase the chance for originality and innovation. Uses of Brainstorming When to Use Brainstorming Generating ideas for kaizens Formulating theories for root cause analysis Evaluating ideas for remedying a root cause Identifying resistance…

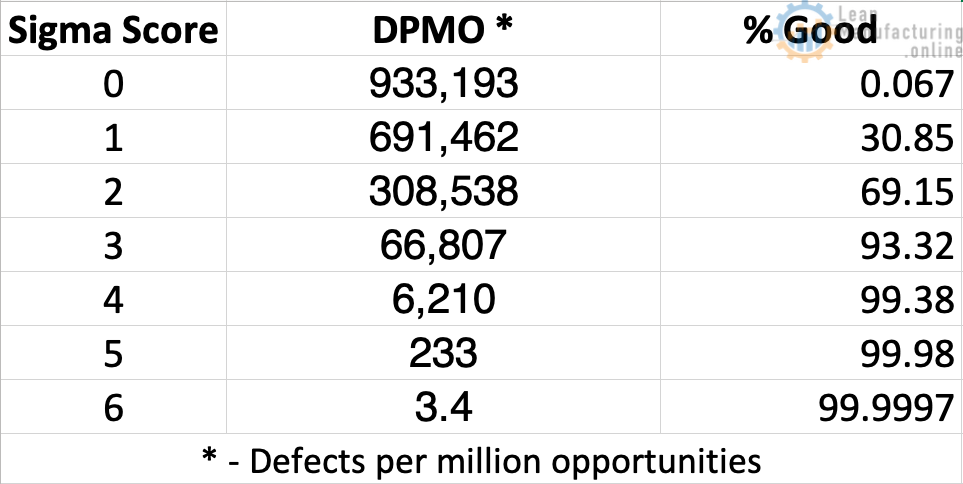

Read More »Six Sigma aims for perfection – Metric and Philosophy explained

Six Sigma tools and methods focus on reducing process variation. Six Sigma Metrics Is 99% good enough? Let’s review some examples: 99% Good (3.8 Sigma) 20,000 lost items of mail per hour; 5,000 incorrect surgical procedures per week; Two short or long landings at most major airports each day; 200,000…

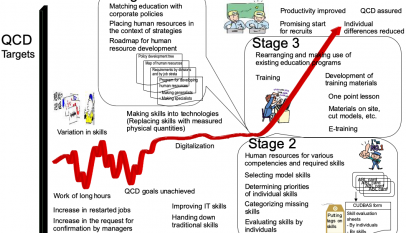

Read More »Creation of a System for Education and Training

Necessity of Education Necessity for Improving Knowledge and Skills in Operation and Maintenance Abilities Required for Machine Operators Ability to detect and repair malfunctions of equipmentAbility to comprehend the functions and mechanisms of equipment and discover systematic causes of abnormalitiesAbility to comprehend the relationship between equipment and product qualities, predict…

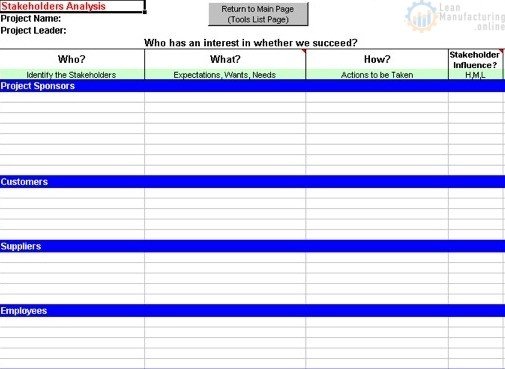

Read More »DMAIC – Define Phase

You might be wondering why you should bother with a define phase. Well, the define phase states the very reason for doing the project. It states the problem to be solved, the goals to be achieved, and the project team that management has assigned to do it. In short, it…

Read More »