Lean Six Sigma

TPM Leadership Training Session – The 8 Wastes

Understanding of the enormous opportunities across the entire enterprise to eliminate waste and improve processes, starting with manufacturing.

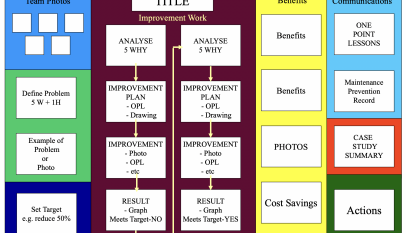

Read More »Focused Improvement Training. CAP-Do and the 16 Major Losses

The packer was equipped with 12 obsolete pneumatic control valves...

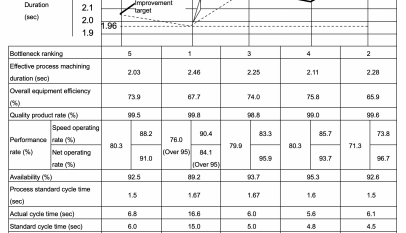

Read More »Overall Equipment Efficiency and Effective Process Duration Calculations Sheet

If, A: Actual working time of one shift = B: Scheduled down time of one shift = C: Loading time of one shift = A-B = D: Stoppage loss time of one shift = E: Operating time of one shift = C-D= G: Number of units processed in one shift…

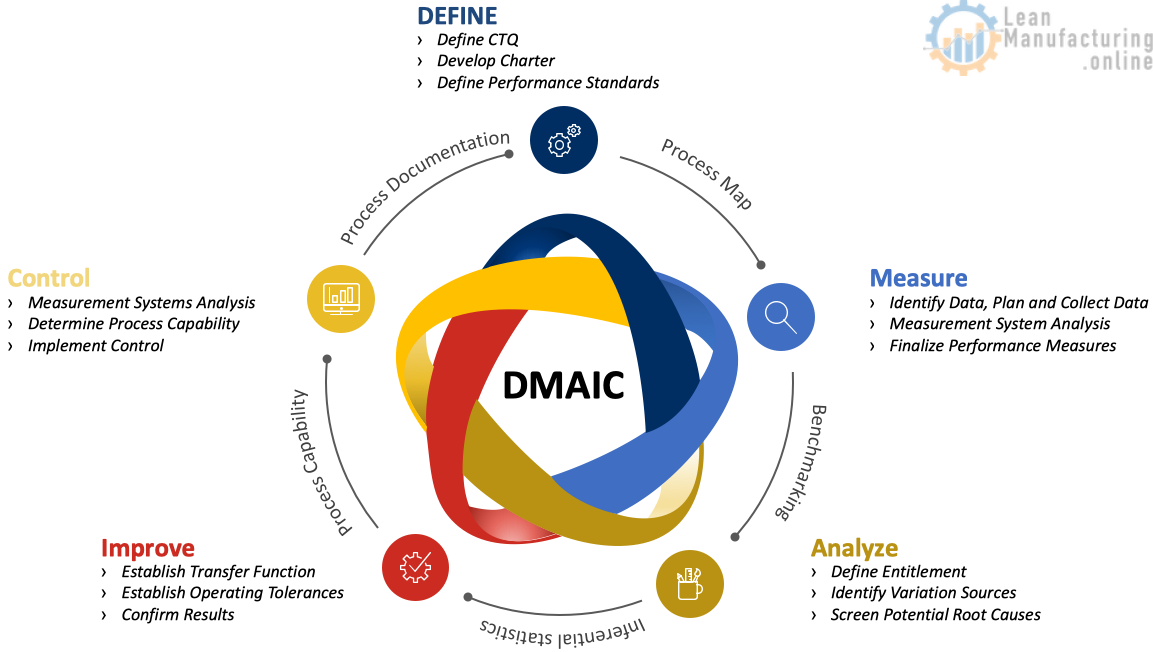

Read More »Six Sigma DMAIC 15 step process

DMAIC (Define, Measure, Analyze, Improve, and Control) is a structured problem-solving methodology used in Six Sigma projects to identify and eliminate process defects. The method involves specific activities and tools that help organizations to identify the root causes of problems, optimize process performance, and sustain improvements over time. Each phase…

Read More »