Lean

Lubrication

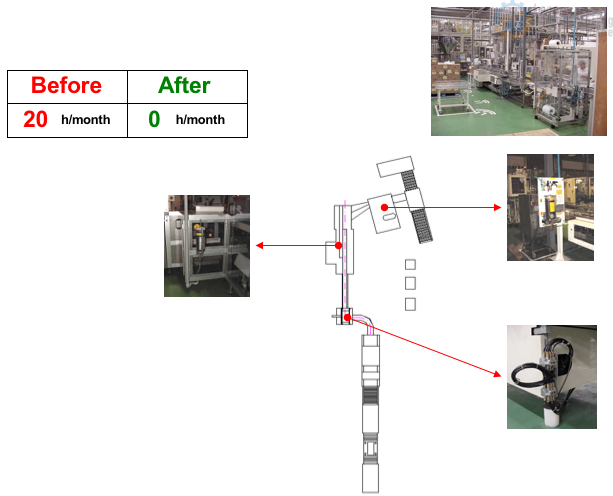

PM Element 5. LUBRICATION PLAN Step 1 Identify the component that needs to be lubricated. Step 2 Determine the right type of lubricant. Step 3 Determine the right method and tools to perform lubrication. Step 4 Determine the right frequency. Daily, weekly, monthly, quarterly. Step 5 Identify if downtime is necessary…

Read More »Steps to create Value Stream Mapping

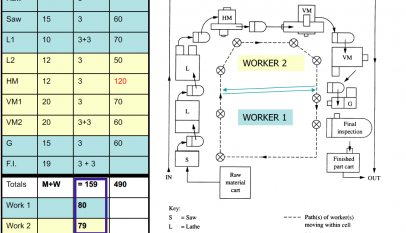

A Value Stream Map is… A tool that helps visualize and understand the flow of material and information as a product or service makes its way through the value stream: A high-level map that visually presents the flow of a product or service from supplier to customer can be used…

Read More »TPM Leadership Training Session – The 8 Wastes

Understanding of the enormous opportunities across the entire enterprise to eliminate waste and improve processes, starting with manufacturing.

Read More »Introduction to the Toyota Production System (TPS)

Brief history of Manufacturing 1980’s OPEC oil embargo drives up fuel prices, Japan imports small cars with increased fuel mileage. How we learned about TPS Quality of cars – but not right awayPilgrimages – Hayes, Wheelwright, ClarkJoint ventures – Nummi-Geo…Japanese NA operations-Georgetown, KYJapanese sages- Ohno, Shingo, MondenAmerican translation – “Lean”,…

Read More »