5 Why Analysis

Lessons Learnt as a communication tool

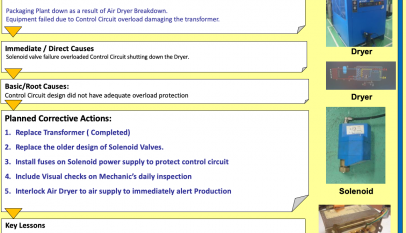

Another great tool to create short but meaningful communication is Lessons Learnt. It can be used to communicate Safety, Quality or Productivity issues to all Team Members. Goal is to explain what happened and how to avoid it from happening in the future. Lessons Learnt Principles applied are to: Take…

Read More »Broken Parts Museum – Analyzing and Preventing Breakdowns due to Forced Deterioration

5 Why Analysis Autonomous Maintenance Blog OPL Root Cause Analysis Training World Class Manufacturing

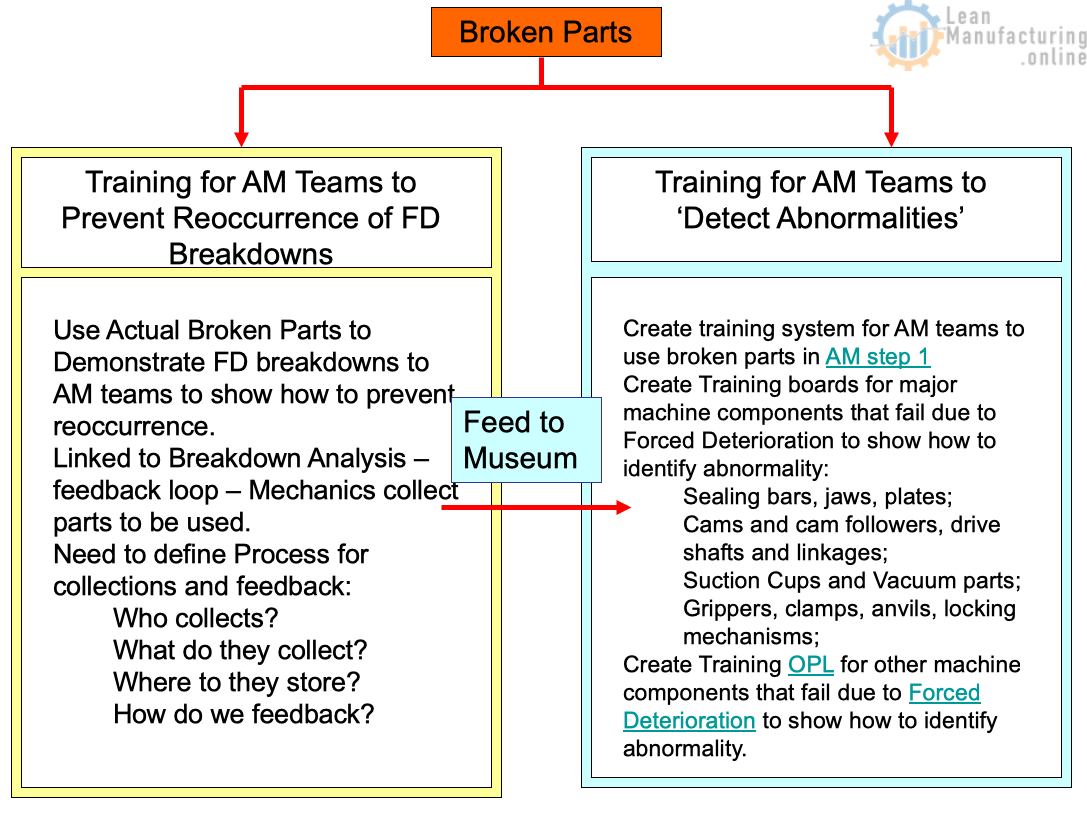

Collecting broken or worn machine parts for later analysis will help to understand root cause of failures, as well as can assist with training AM team members. Training for AM Teams to Prevent Reoccurrence of Forced Deterioration Breakdowns Use Actual Broken Parts to Demonstrate FD breakdowns to AM teams to…

Read More »Approaching Zero Breakdowns by advancing Breakdown analysis

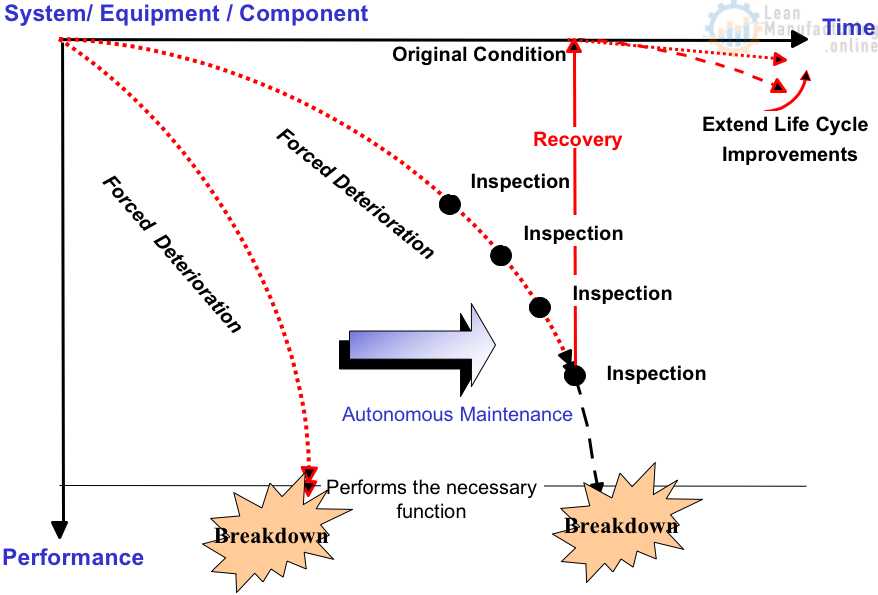

What is Maintenance? Maintenance: It is a set of developed, organized and administered activities with the aim to economically viable ensure the operational status of a specific system. The 7 steps concept of Autonomous Maintenance (operators) are similar to 7 steps of Planned (Effective) Maintenance (trades): “the left and right hand…

Read More »5 Why Root Cause Analysis (RCA) – One Point Lesson (OPL)

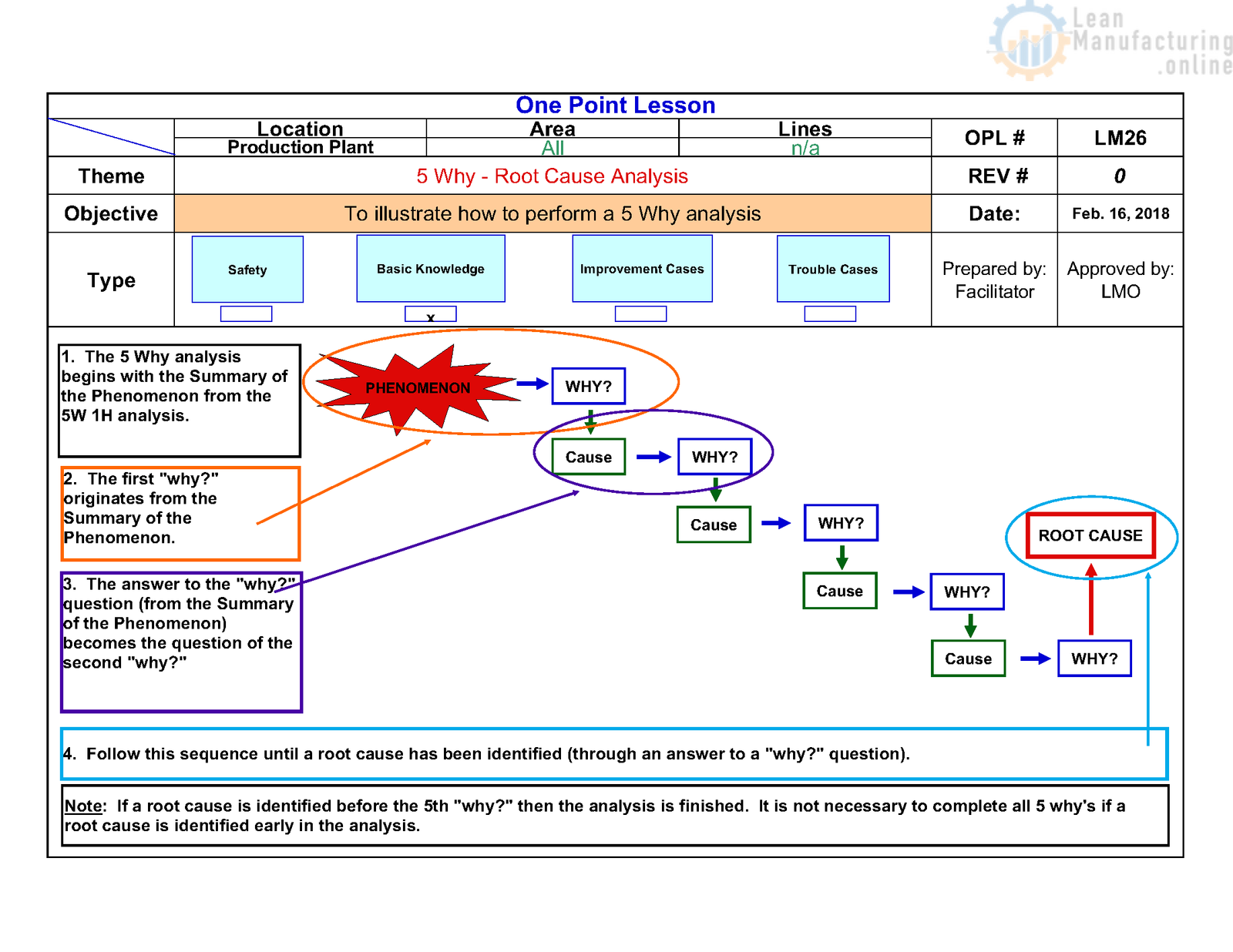

5 WHY Analysis is the key tool used to determine ROOT CAUSES for the Phenomenon identified in theCHECK Phase of CAP-Do. The 5 Why analysis begins with the Summary of the Phenomenon from the 5W 1H analysis. The first “why?” originates from the Summary of the Phenomenon. The answer to…

Read More »